By Olivia Cahoon

Museum graphics are in constant demand as new exhibits require advertising, entryway signage, and printed pieces for the exhibit itself. To keep up with a diverse set of requirements, print service providers (PSPs) that offer museum graphics often rely on a variety of digital presses and even seek help from professional design studios.

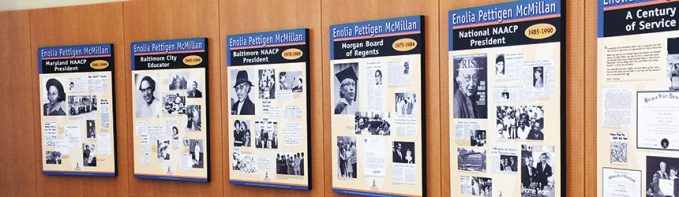

Above: Alpha Graphics, of Baltimore, MD< offers a variety of museum graphics, including cut vinyl, photography printing, and fine art on velvet paper or canvas.

Exhibiting Pride

Museum graphics allows PSPs to create unique pieces with high exposure. As each piece is custom printed according to the exhibit, it’s important that PSPs use a range of technologies and capabilities that match the correct ink and media to the application.

Established in April 2005, SignCenter, LLC started in the basement of a picture framing shop in Middletown, CT. With one employee, the sign shop originally supplied wholesale signs and digital graphics to retail print shops.

It since grew into a wholesale PSP with 14 employees operating in a 24,000 square foot facility in Milford, CT. The PSP offers UV, latex, solvent, and aqueous prints, dye-sublimated (dye-sub) fabrics and boards, die cutting, acrylic signs and engraved signs, and full sewing and finishing services.

In 2008, SignCenter started working with museums. “One of our signage customers does a lot of work with a local Ivy League university and were asked if they could supply graphics for a large retrospective exhibit,” explains Michael Oliveras, owner, SignCenter.

Today, five to ten percent of its overall output is for museums. As a wholesale printer, the shop creates graphics for the Barnum Museum, Florence Griswold Museum, Mystic Seaport, the Museum of the City of New York, the National Building Museum, the Venture Smith traveling exhibition, and Yale University galleries.

SignCenter employs an arsenal of digital printers for its museum graphics—updating the presses on a four year schedule to ensure optimal output. For museum work it uses an EFI VUTEk GS3250LX, Epson Stylus Pro 7400, Océ Arizona flatbed from Canon Solutions America, and an OKI Data Americas ColorPainter M-64s—depending on the application.

“Having a range of technologies and capabilities helps us match the correct ink and media to the application,” says Oliveras. “A lot of effort is spent maintaining accurate color profiles across the printer platforms to ensure that, for instance, boards and decals produced for an exhibit have consistent colors.”

Museum graphics’ materials are project dependent but include white ink on mylar wrapped medium density foamboard (MDF) boards and carbonized bamboo plywood. In fact, Oliveras notices more museums requesting higher quality and greater depth of sublimated prints on aluminum, glass, and MDF as well as silicone edge graphics. “We have created interesting effects for exhibits using mesh banner material as a theatrical scrim, and printing on historic canvas materials.”

Its software consists of an EFI Fiery, Onyx Graphics, Inc. solution, and Wasatch Computer Technology, LLC RIP depending on the output device. Museum graphic finishing is completed with a Zünd digital cutter and Summa America LLC S Class T140 digital plotter.

Museum graphics gives SignCenter the opportunity to create unique pieces with high exposure. However, Oliveras believes the real benefit is his employees’ personal satisfaction when they see high-quality work in a legitimate environment. “They don’t have the opportunity to see our corporate interiors and the day-to-day point of sale/point of purchase, and typical production work does not have as high a profile,” he admits.

The PSP experiences occasional challenges when working with museums due to demanding color and quality standards. However, SignCenter is well prepared and dedicates a production specialist—some times for a day—to work directly with the designers to print proofs and samples and make adjustments until the designs and curators are completely satisfied with the output.

Lighting can also require strategic planning. According to Oliveras, museum lighting is usually tightly controlled, and is not often the full spectrum of light used in print shops. “It is critical that samples be evaluated in the display environment to ensure proper color and contrast performance,” he suggests. To eliminate reflection, SignCenter uses 3M Commercial Solutions 3M Scotchcal Ultra Matte Overlaminate 8915.

Designed for Admission

In 1995, wife and husband Deanna Chrislip and Brian Hale created Design WorkShop, Inc. to provide complete graphic services to businesses, non-profit organizations, and municipalities. The design shop started in the owners’ home and now operates in a 4,800 square foot studio in Indian Orchard, MA.

Over the years its staff size has varied. The company currently has two full-time employees and several contract workers on call. “We also have developed good relationships with reliable suppliers and subcontractors enabling us to provide a variety of services to our customers throughout New England,” says Deanna Chrislip, owner, Design WorkShop.

When the shop first opened it used an Encad 36-inch inkjet printer and a Roland DGA Corporation ColorCAMM Pro PC-600 thermal transfer printer/cutter. “We understood then how important large format printing was to our business. What we didn’t understand was how quickly the technology would improve and how difficult it was to maintain a machine in top working order in a small shop,” explains Chrislip. “We quickly discovered that we could be more productive and provide our customers with more options and better quality if we used a service bureau.”

In 2011, Michael Oliveras of SignCenter in Milford, CT approached Design WorkShop for design services. According to Brian Hale, owner, Design WorkShop, the company was attracted immediately to SignCenter’s exceptional quality and service along with a variety of products.

The design firm now works with SignCenter on several museum applications such as printed vinyl graphics. This includes two recently completed large murals for the new Amazing World of Dr. Seuss Museum in Springfield, MA. Together both companies produced exterior printed vinyl banners, exterior signs with laminated vinyl mounted on aluminum composite material (ACM), and direct printed panels on PVC, plastic-faced foamcore, and ACM.

“Museum graphics can effectively draw the viewer into the exhibit and provide informational details to enhance the experience,” comments Chrislip. “Cut vinyl letting continues to be important for titles, quotes, and informational text.”

The Dr. Seuss Museum is the newest museum in association with the Springfield Museums. Including the Dr. Seuss Museum, the organization encompasses five exhibition centers including two art museums, a science museum, and a history museum. Design WorkShop handled its first project for the Springfield Museums in 2008. It started working with the curator for the Michael and Donald D’Amour Museum of Fine Arts to provide cut vinyl lettering for changing exhibits.

Most of Design WorkShop’s work is completed with Adobe System Incorporated’s Creative Suite, Illustrator, InDesign, and Photoshop. “We primarily use Illustrator because of its versatility and compatibility with other programs,” shares Chrislip. SA International’s FlexiSIGN Pro is used for cut vinyl projects.

Other projects for the Springfield Museums included exterior bronze lettering; wayfinding signs; ADA interior signs; banners; large format vinyl prints; dye-sub fabric hangings; lettering and graphics for a parade float, exhibit, and display materials; small informational labels for individual artwork, as well as printed brochures and rack cards.

Chrislip and Hale both have backgrounds in the arts and are strong arts advocates, so working with organizations like the Springfield Museums are ideal. “The work is always interesting and we enjoy the variety of projects and the opportunity to work with other creative people,” offers Hale. Over the past few years, arts-related projects have increased to comprise about 30 percent of overall business.

Well-Prepared Printers

Alpha Graphics, Inc. started in 1972 as a photo lettering shop and service bureau in Baltimore, MD. It originally offered typesetting, photo lettering, film for letterpress and offset plates, quick printers, faxing, passport photos, and posters.

In 2007, the shop underwent new management and added services in professional graphic design, trade show displays, fine art reproduction and giclée, and museum graphics, including cut vinyl, mounted panels, and color transfers for labels. “While we had the fortune to add these services, we keep our boutique shop feel and customer service at heart,” says Christine Walsh, president, Alpha Graphics.

Working with museums since 1972, Alpha Graphics originally supplied color transfers and produced graphics and panel prints for museums of all sizes across the country. While the method and materials changed over time, Walsh believes there is always a need for museums to partner with local shops for production.

Its museum graphics offering varies, including cut vinyl, photography printing, and fine art on velvet paper or canvas. Alpha Graphics offers both archival and non-archival canvas reproduction options with different price points.

At least 20 percent of the shop’s sales comes from museums. It has worked with a variety of organizations, including the Baltimore Museum of Art, John Hopkins Evergreen Museum, National Museum of American Jewish Military History, Stanford Museum, and the United States Holocaust Memorial Museum.

“Because we’ve worked with museums for over 40 years, we are well versed in what museums use or should use. I’ve also made it my purpose to become well educated on new and exciting materials that become available,” comments Walsh.

Alpha Graphics’ most used product for museums continues to be its proprietary Alpha Colors technology, also known as rubdown color transfers or Chromatech. Alpha Colors are color transfers that are highly detailed graphics used for museum labels, product mockups, and even items in film scenes used by Hulu and Netflix.

For digital technologies, the shop selected the Roland TrueVIS VG-640 for its Pantone and profile matching. More frequently or when large size dictates, the PSP uses the Roland press with petroleum-solvent ink, which Walsh says is very durable over time and in a variety of environments. “We are also able to add a UV-resistant lamination to pieces that will be in direct sunlight, enhancing versatility for non-traditional exhibits.”

Alpha Graphics also uses an Epson Stylus Pro 9890, which allows the company to print on archival materials for museum panels that need to be preserved or go into cases without off-gassing issues. According to Walsh, this press does a great job with photo reproductions or archival pieces that must meet the Maryland Historical Society’s guidelines. It is especially well fitted for the shop’s premium photo prints, fine art, and high-quality bond production for testing and color.

According to Walsh, selecting the proper materials and equipment for museum graphics harbors a better relationship between the museum and PSP—granting repeat opportunities. “Museum staff are usually eager to work with a printing company they trust. When you educate them on what materials would work and what materials would not, they are able to get past the ‘not sure what you mean’ and get to the ‘ah-ha’ moment,” admits Walsh.

Museum-Ready Signage

Designers and PSPs like Alpha Graphics, Design WorkShop, and SignCenter use digital printing technologies to keep museum clients satisfied. By doing so, each company harbors a healthy partnership and receives repeat job opportunities when new exhibits and the need for updates to existing exhibits arise.

Dec2018, Digital Output