By Digital Output Staff

Labels are printed on both narrow and wide format digital devices. While wide format is typically more geared toward short-run stickers and decals, narrow format machines—usually around the 13-inch print width mark—offer a more traditional approach to the term label. The digital label printing segment continues to grow, especially in shops were traditional analog technologies were once the norm. We spoke with two print service providers (PSPs) who have always offered label printing in some capacity, but have enhanced their output with the advent of digital.

Their customers benefit from a wider variety of choices when it comes to label designs. Color and variability between versions are high on the request list, as is media compatibility. If customers benefit, so too does the PSP.

Label Freedom

Southern Coating & Nameplate Inc. (SCN) began in 1970 by Bob Osborne. It offers a range of industrial printing services, including silkscreen, flexography, wide format digital, roll-to-roll digital, doming, metal, and laser die cutting to customers nationwide. 35 employees work out of a 55,000 square foot work area based in North Little Rock, AR.

About 85 percent of the company’s business is considered label printing. Most of this is focused on the industrial segment.

Order quantities range from 500 to over 1,000,000.

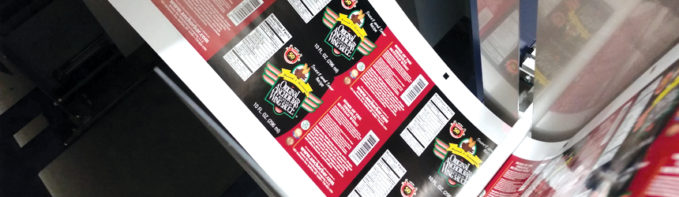

For the past 15 years, the print provider has used digital printing equipment fin different forms from Gerber Technology Edge print-to-cut solution to Roland DGA Corporation SOLJET wide format printer/cutters and Fujifilm North America Acuity flatbeds. It recently added Tau LFS 330 label printer from Durst Image Technology US LLC. 60 percent of the company’s label work is produced on the Durst Tau LFS 330.

“The Durst Tau LFS 330 was the next step to adding a high-speed digital rollto-roll press with good ink durability to our arsenal. We wanted to offer our customers faster lead times, better quality, and more competitive pricing on both small and large jobs. Our expectations have been far surpassed of the capabilities of our press,” explains Scott Adams, VP, SCN.

Equipped with an inline laser finishing system, the printer uses CMYK plus orange, violet, and white. This paired with its print speeds of up to 157 feet per minute intrigued Adams.

Additionally, since the company focused on industrial print, it needed its ink set to offer durability without any lamination or coating processes added—the Durst Tau LFS 330 provides this. The deciding factor in the eventual purchase was Durst’s customer service, which Adams believes sets them apart from other vendors on the market.

Implementation was smooth and the staff at SCN was producing actual jobs on the first day of training on the Durst Tau LFS 330. After a week, the printer was fully operational. Jobs once run on older technologies are consistently being moved over to the Durst press.

SCN still uses traditional methods for label printing. Adams says the deciding factor when going between digital and an analog press is whether the job at hand can fit on the Durst’s print width—13 inches with 13.5-inch material.

It’s the width and the ability to print a quality metallic color that Adams sees as the biggest limitations to digital printers in general. Although, he is aware that changes in print width and metallic colors seem to be on vendors’ radars and are in the prototype stages of development.

All in all, the Durst Tau LFS 330 has truly changed labels for SCN’s customers. According to Adams, digital allows for an unlimited arena when it comes to designing label graphics. For example, if a label uses ten colors and is printed digitally, the price is not nearly as high as it would as been in the past. That is when most customers would have opted for a one-color label instead.

Another feature enticing to the customer, variability. “Digital gives the customer more freedom to design, size, shape, detail, and color. Variable information was virtually impossible with traditional type printing,” continues Adams.

The benefits propel SCN to continue monitoring the upward swing of digital print and its Durst Tau LFS 330 has helped to position the company to mirror that growth.

A Hit on Color

Based in Sanborn, NY, Sharp Printing Inc. began in 1984. A staff of eight work out of an 8,000 square foot shop to service customers nationwide. Its main services are commercial, business to business, and wholesale print. A major part of its offerings included sheetfed work, but in the last eight years it’s transitioned to roll to roll thanks to digital.

As the team at Sharp Printing noticed its commercial print work dwindle, it recognized it was going to Web-based businesses or companies were bringing it into their offices—something it couldn’t compete with. To make up for the loss, Slade Sharpsteen, owner, Sharp Printing, noticed that the company was still receiving a lot of requests for labels. However, it was outsourcing or sending away these jobs.

To remedy this, it invested in a small digital press that could handle B&W labels and began offering the service to its customer base. At the beginning of this transition, labels accounted for about 40 percent of Sharp Printing’s business. Now it makes up 70 percent of the work.

To keep pace with the growing label requests—and offer its customers a higher quality product—the print provider purchased an Epson SurePress L-4033AW a little over a year ago. A few different reasons went into why this particular 13inch press with white ink was chosen.

According to Justin Sharpsteen, engineer, Sharp Printing, media compatibility was a pivotal issue. Its older digital press wouldn’t work with polypropylene label media—the machine would run too hot for this material. The SurePress has no issues and is ideal for foils and clears as well.

Another feature that was top of mind when choosing a new device, ink choice. The Epson SurePress L-4033AW provides a bigger range and more control of color. For example, the additional use of orange and green ink really changes what Sharp Printing can offer customers. The old equipment had a problem running a neon green and the Epson device hit it on the first try.

Typical label quantities run from 250 to 10,000—most of which are printed on the Epson SurePress L-4033AW. Justin Sharpsteen says there are no limitations to the press, as far as he has experienced— and if the work load somehow doubled over night, he would purchase a second SurePress in an instant.

“Labels will grow. We can now do higher quality work, can match anything for a roll label. Existing customers love the color quality and it’s dead on every time—whether it was run two days or two months ago,” he continues.

And that neon green the Epson SurePress L-4033AW hit on the first try? It was for a prospective customer that manufactures its own wing sauce—now it’s a current customer.

Sky is the Limit

SCN and Sharp Printing are well versed in how to grow a smaller segment of a business into a larger one. The PSPs’ experiences incorporating digital label production into their shops has left them with an even greater appetite for the market. Both recognize the benefits digital print brings to labels from expanded color gamut to increased media compatibility, and more importantly what these benefits mean for their customers. The sky is the limit when it comes to digitally printed labels.

Click here to view the Digital Label Printers Target Chart – an all-inclusive information resource!

Oct2016, Digital Output