By Cassandra Balentine

Building wraps and wallcoverings are an excellent way to incorporate art, branding, or wayfinding messaging in a less traditional manner. However, buildings often include textured elements like brick and concrete that may not be as easy to apply a pressure-sensitive adhesive (PSA) material to compared to a smooth service like a window.

Print service providers (PSPs) utilize specialty PSA print media and laminate solutions for a variety of wall surfaces, including textured surfaces. This enables a building wrap or wall graphic to fit into the overall look and feel of the environment it is placed in.

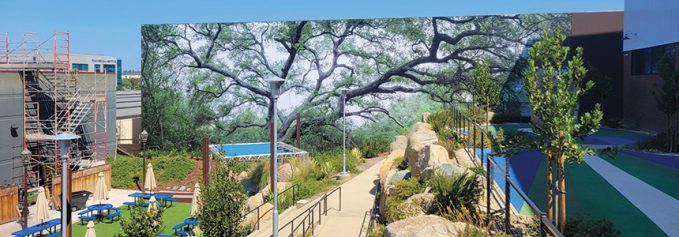

Above: GF 285 RoughMark White and GF 287 RoughMark Clear are General Formulations’ solutions for textured wall graphics/wraps. This wall wrap was created by SpeedPro Mission Valley.

Adding Opportunity

Building wraps and graphics help businesses and municipalities optimize previously untapped areas for art, messaging, and promotional purposes.

“Building wrap material was a fun new way to advertise or customize when first introduced as an alternative to banners and paint. With COVID-19 being around the last couple of years we are seeing more of these products in use for directional and informational purposes,” shares Michael Aldrich, product manager, FDC Graphic Films, Inc.

Jay Kroll, product manager, cut and craft films, wall and transit media, General Formulations, notes that “this space has been growing for years with the evolution of adhesive and film technology, and demand continues.” Rather than print on large banners that require holes and fasteners to be drilled into the wall, adhesive-based building wraps allow for beautifully printed advertisements and messaging that can be changed out with ease, with no lasting damage to the underlying surface. “This ability to use more surfaces for communication with customers gives the PSP and its customer more options to determine the best way to promote their brand or share information with the masses.”

Designers and advertising agencies continue to discover and utilize wide format print media for walls, including those with textured—brick, block, and stucco—surfaces. “These specialty applications work well on their own or as part of an overall design that can include both floor and window components,” shares Ross Burnham, senior marketing manager, Mactac. He sees these products finding their way into a range of locations including healthcare, schools, restaurants, sport complexes, museums, and parking garages.

“The benefit of building wraps is that you can take an otherwise empty surface and create a point for messaging without the need for a major construction project, and you can add temporary graphics for a weekend charity event or have year-long installations that highlight certain students or programs on common walls of a college campus,” says Kroll.

Additionally, these wraps work on odd shapes, evoking a look like it was painted on and has always been there, according to Aldrich.

“As with floor graphics and wall murals, the expansion of application capabilities for PSPs, along with end-user awareness for all the surfaces they can use to communicate their messaging, only helps to increase the demand for building wraps of all sizes and styles,” adds Kroll.

Getting it Right

Building wraps and graphics present certain challenges, especially on textured surfaces. However, many of these are avoided with skilled installers and the right materials.

Each building type offers a variety of considerations that should be factored into the wrap or graphic. “Surface type, surface profile, surface treatment, surface roughness, durability requirements, short or longer term, UV exposure, full, partial, or street level only—each building is different,” notes Jodi Sawyer, strategic business unit manager, FLEXcon Company, Inc.

Understanding the building code requirements and making sure the materials used comply with local regulations such as flammability and smoke spread testing is essential. “The time and cost involved with the installation of a building wrap means there is a high risk if the media does not perform as expected. Replacing graphics isn’t easy, so it’s important to work with a manufacturer that can recommend the right product for the application,” she adds.

“Depending on where you are located and the time of year, it could sometimes be challenging to look for days that are clean, dry, and in the right temperature range to ensure the proper bond between the media and the wall surface. The aggressive adhesives can be forgiving, but there is no substitute for proper wall preparation,” admits Kroll.

Textured surfaced building wrap projects can be some of the most complex for the wide format print applicator. “The site needs to be inspected to ensure the correct surface preparation is made for a safe and successful installation. These types of applications typically require heat from either a torch or a heat gun to be utilized to help soften and then to ‘reset’ the memory of the film being used. This ensures a strong bond to the rough surface and provides the appearance of the image being painted on. A good amount of effort is needed to achieve a great looking wall graphic that will benefit the end user for years to come,” shares Burnham.

Most exterior surfaces have some texture, so when planning graphics for outdoor walls and columns, Micah Causey, VP, FloorSignage, LLC, says it is critical to select a material that not only conforms to the texture but also maintains an adequate bond to the intended surface.

It’s likely that the surface of buildings and walls will be rough, so the need for graphics that will adhere to textured surfaces is widespread. “Concrete, concrete block, and brick are commonly used materials for commercial buildings and walls. Stucco is more prevalent in some areas than others, and rough surface granite is often used in public, commercial, and stadium and arena construction, making it highly likely that graphics will need to adhere to a surface that is textured. Think of hotels in Las Vegas, NV or Los Angeles, CA; or near or around any professional or college sporting event as well as urban renewal projects where new communities are being developed and construction often features brick or concrete,” notes Sawyer.

Trends in building materials change based on design preference, durability, cost, and sustainability factors. “New materials, such as cross laminated timber made from renewable wood are being used as alternatives to concrete. Wool bricks are becoming popular for their durability and resistance to cracking compared to traditional brick. When building and wall surfaces change, the media adhesive required to adhere to wool and wood may be very different than standard products today. It’s important to understand the surface characteristics and work with a manufacturer who can provide application-specific tested materials for evaluation in the design phase,” shares Sawyer.

“The most important rule is do not go cheap,” stresses Causey. He suggests seeking out top-quality materials that are pliable, conform, and reliably hold up to freeze/thaw cycles as well as harsh sunlight. “Not all materials install the same way so it is equally important to follow the manufacturer’s installation instructions so the graphics bond and remain adhered to the intended surface.”

Creating a Buzz

From design to graphic placement, building wraps are created to make an impact. As they become increasingly popular, new trends emerge.

For example, designers incorporate wide format, PSA print media as part of the environmental aspect of their building design. “The ability to include rough wall surfaces as part of this work broadens the options for the final design,” offers Burnham. “What was a plain white block wall can now be included into the overall design to support school spirit or brand messaging, or delight a young hospital patient with images of a giraffe or a spaceship.”

Causey sees many trends that stand out in this space. One includes retail stores wrapping their buildings with seasonal and holiday-themed designs such as Christmas packages or decorations. Another involves municipalities using large wall murals as art projects to beautify a city block or neighborhood. Businesses are also transforming the walls of parking garages, both inside and out, using the space for branding or to create an environment themed to the business as customers drive into the garage.

Aldrich says businesses are customizing building wraps specifically to promote what that business is all about. “For example, breweries could display their logo and a large mural of people celebrating with mugs of beer. Something displayed that’s the size of your building is bound to build some serious buzz.”

In addition, media that gives a graphic the look of movement or light—glitter, holographic, embossed—helps bridge the gap between static graphics and digital displays, offers Sawyer.

In another direction, Kroll sees the use of wrap materials for wayfinding, such as differentiating levels in parking structures with different colors or graphics to help people associate an image with their parking spot. “These graphics on smooth concrete are often paired with a protective layer, making the graphics look great while providing additional protection from graffiti, dirt, or fading of the ink from UV exposure.”

Additional wayfinding wall graphic trends have developed as a result of COVID-19. Retailers use these as a tool to communicate with shoppers picking up an online order, notating an online order entryway, or restaurants marking takeout or delivery service areas on a building. “COVID-19 has conditioned consumers to look and respond to wayfinding and distancing messages placed on walls and floors,” admits Causey.

Back to Basics

Building wraps and wall graphics must compete with a variety of more traditional sign graphics, as well as digital displays.

Even with the expansion and accessibility of digital displays for advertising, static installations are not going away, stresses Kroll. He points out that vinyl wall graphics are flexible not just in their physical structure, but their ability to easily go up in places where the cost and logistics of a giant LED screen just don’t make sense.

“Let’s go back to our ‘sign roots’ for a moment when large department stores, restaurants, and hotels would paint ads on the sides of the buildings, or the building next door to advertise what their business was about,” recalls Aldrich. “With building wraps, customers respond more actively and look forward to seeing what the next few weeks or months might bring. They become part of an ever-changing landscape bringing brand awareness to what your business is about. Digital is everywhere—it has its place, but there is something about the old school feel that digital can’t reproduce.”

“Building wraps and wallcoverings are tied to consumer mobility and advertisers being able to reach consumers where they live, work, and play. Despite the shift in the location of where this happens, building wraps and wallcoverings—static or digital—play an important role in conveying brand messaging. Static building and wall wraps facilitate engagement and amplify digital ads,” offers Sawyer.

Causey admits that digital displays can be obtrusive, but he says a good designer and the right material can enhance the appearance of a building by integrating applied graphics into the architectural design. “This approach can highlight specific parts of a structure or use a topic such as nostalgic graphics to create a vintage aesthetic. Using the right material allows for flexibility to rotate these out periodically. In old photographs of cities, large graphics painted on the sides of buildings are common sights, which is proof this application has been and will always be highly visible and effective.”

“Design will always factor into the relevance of building wraps versus digital displays—whether the look is clean or creative—and determine the impact those installations will have on the success of the campaign. The beauty is that the advancements in wrap media technology are quickly making it so the print media is not the limiting factor when it comes to creating a stunning visual vinyl display,” comments Kroll.

“Whether it’s a local business or a national event, the scale, target-ability, and amplification of using a building or wall graphic to convey a message is powerful. In particular, static building and wall wraps are easily adapted to different locations, they give dimension to the creative in a way that digital displays can’t, and enable placements where digital displays are not feasible,” adds Sawyer.

Cost Considerations

Determining the cost effectiveness of a building wrap is an essential step. However, pricing often depends on the scale and objectives of the campaign.

Kroll admits that the cost of building wraps can be high as the media is typically specialized and more expensive, not to mention the additional permitting, equipment, and installation time required. “But these factors exist with digital displays, which have a much higher initial cost and the ongoing expense of power and maintenance. Painted advertisements lack the changeability of a building wrap, making the flexibility of a vinyl building wrap significantly more cost effective for marketing campaigns,” he stresses.

Building wraps that utilize PSAs can provide a long-lasting print image without the need to alter the building with mechanical fasteners or clamps. “The end user will also discover that when it is time to remove the graphic, the combination of media and laminate will remove without leaving any adhesive residue on the wall surface,” suggests Burnham.

“Building wraps alone can be a tremendously effective media depending on the placement and potential capture audience, and the number of impressions. That’s why they are continuously in place in markets like Las Vegas, NV where the people impressions are high and regularly change. Compare a building wrap to a transit bus poster or wrap and there is a significant difference in cost based on the scale and complexity of wrapping a building versus installing bus posters and wraps,” offers Sawyer.

Aldrich also believes building wraps can be more affordable than the alternatives, like billboards for instance, which can cost around $3,000 a month. “A full building wrap in a similar size may cost around $10,000 depending on the size and surface of the installation. Your wrap will pay for itself in a few months, the rest of the wrap life is like a free advertisement,” he states.

Not Going Away

The application of building wraps and graphics continue to evolve to support new trends and demands. One thing for certain, these applications are here to stay.

Kroll points out that the more PSPs know about their options in this space, it will help increase their confidence for suggesting these types of wraps, and ultimately grow their bottom line.

Burnham agrees, adding that as more designers, brand owners, and PSPs discover the capabilities for this type of product, demand will continue to increase.

Sawyer feels that we are entering a renaissance where outdoor advertising—including applications such as building wraps—will be a form of art, serve a purpose, and engage on many levels with targeted, meaningful messages that allow people to connect locally and socially. “The creative designs inspire people to take pictures of billboards and buildings and share them on social media—connecting the physical and digital worlds. Consumers are tired of spending so much time in front of screens, and the physical, experiential world invites us to engage as we slowly emerge from the pandemic,” she notes.

Aldrich predicts the demand to continue, as it is generally a cost-effective way to advertise a product or business allowing the customer to get the look they want and change out as needed easily, while still creating the thrill and keeping an iconic look at the same time.

Big and Bold

The use cases for building wraps and graphics continue to grow. From art to advertising, these applications add beauty and purpose to an often underutilized medium.

“Building wraps are impactful and make a big statement or can beautify a structure. Both objectives can be a good investment for the client,” states Causey.

We expect to continue to see demand for building wraps, and along with it the need for media that adheres to the textured surfaces that installers often encounter in these applications.

Dec2021, Digital Output