By Melissa Donovan

Converting equipment is traditionally used by media manufacturers and distributors. However, there is a shift in the wide format end user community where roll or log slitters are purchased by print providers to convert media before and after production runs.

Slitting involves cutting a roll of media into narrower widths. Converting and slitting are similar terms, however converting can also include rewinding. Rewinding equipment involves transferring media from one roll to another. There are separate rewinding devices, and rewinding is a feature sometimes included on a roll slitter.

Bringing slitting or rewinding in house allows print service providers (PSPs) to better control inventory. “Implementing a converting center allows the print provider to rewind, trim, and slit media to the exact size required for the job. This eliminates stocking different widths and lengths of print media and provides more control over the total media used for each job—as only the required amount of media needed is delivered to the operator for printing,” explains Chase Pender, marketing manager, Supply55, Inc.

Once implemented, a roll slitter converts many types of materials. This includes banner material, heat transfer vinyl, film, perforated window media, magnets, photo paper, canvas, and VHB tape. In each case, larger rolls purchased directly from the manufacturer are easily converted or slit to compact, more manageable sizes.

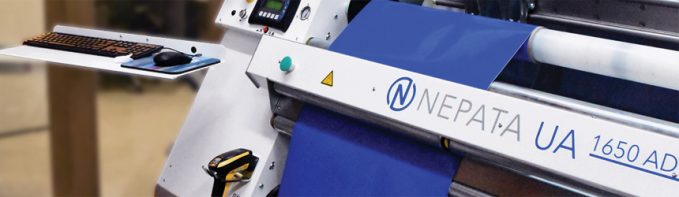

Above: Many types of material can be converted on NEPATA UA Series converters from self-adhesive, sandblasting, masking, vehicle wrap, flex, flock, and window tint films to banner material, photo paper, papers, wallpaper, mesh, dye-sublimation transfer paper, and digital magnetic. NEPATA converting systems are distributed in the U.S. by Supply55.

Translating into ROI

According to Pender, the cost to implement and own a converting system ranges from $25,000 to $50,000 depending on the equipment. Return on investment (ROI) is based on the volume of media processed. In Pender’s experience, customers typically see ROI during the first year of operation.

“As with any new project, time should be spent properly training staff on the use of the equipment. The benefits of in-house converting outweigh the challenges, as users see an immediate payback through better inventory management,” he adds.

A number of market share players make up the converting space. We’ve included some roll slitter vendors here, sharing their converting equipment suited for PSPs in wide format.

Roll slitters can be equipped with one or multiple cutting blades and can also handle one or even two rolls on one device. Also to note, there are manual, semi-automatic, and fully automatic converting equipment. For this article, we’ve tried to focus primarily on fully automatic roll slitter options.

ALS specializes in the design and manufacture of precision roll slitters. The S-Tec line of slitters automatically slits logs or rolls of non-woven textiles, vinyl, technical tapes, pressure-sensitive tapes, self-adhesive materials, foil, PVC, polyester, and polyethylene. Using a hydraulic slitting action and servo indexing system for accurate slitting, the device is compact and offers a user-friendly control system. The system is able to cut up to four different widths per cycle. It is available in widths of 63, 72, or 83 inches and diameters of 12, 16.7, 20, 24, and 28 inches.

Cevenini USA LLC, with its parent company based in Italy, offers the TNF 7 automatic log slitter with a toothed blade cutting system. The machine is ideal for cutting polyethylene, coated and non-coated plastic films, protective tape, and silicone paper. Fully automatic—with the exception of loading and unloading the material—a scissor lift allows the roll of media or log to be raised to the same height as the shaft on the machine. Its working width is 70 inches, however Cevenini does offer customization for all customer requests.

Lever Manufacturing Corporation makes automatic single-knife lathe slitters. These machines use a single circular blade to cut rolls of material on a core into smaller rolls, allowing for fast, accurate slits of varying widths. Its LS-1500 model is an automatic single-roll slitter designed to convert foam, tape, foil, rubber, non-wovens, textiles, and laminates. A maximum roll diameter of 16 inches and maximum roll width up to 90 inches is ideal for continuous production environments with minimal maintenance requirements.

Ribamatic’s newest roll slitter is the Top 50, a fully automatic converting system. The roll cutting device includes one cutting head with the ability to slit up to a diameter of 20 inches and a length of either 120 or 200 inches. A wet blade device means the blade is kept cool throughout the converting process. The machine includes an automatic blade sharpener. It is recommended for slitting fabrics and textiles, polyester, PVC banners and mesh, vinyl, banners, magnetic material, tapes, and paper.

SmartSlitters, a division of Rosenthal Manufacturing, Inc., offers the Enterprise automatic log slitter. Its cuts a variety of materials from adhesive tape, banners, fabric, and window film to magnetic and reflective tape. This is thanks to the PowerBlade—a variable speed, circular blade. Enterprise can be equipped with a rewinder option, allowing the user to transfer material from a jumbo log onto a recovery core. It is available in a maximum roll width capacity of 62 inches.

Supply55 is the master distributor in North America for German manufacturer NEPATA GmbH’s converting equipment. The 65-inch NEPATA UA1650 ADWS is a converting center for film media with high-precision rewinding and automatic cross cutting. It features a rewinding speed up to five feet per second with 99.9 percent rewinding accuracy. The NEPATA UA1650 ADWS is ideal for processing self-adhesive films, masking films, vehicle wrap films, magnetic films, banner material, photo paper, wallpaper, and mesh.

In April 2018, Supply55 in partnership with NEPATA, released the new NEPATA UA770 30-inch smart rewinder/trimmer. Capable of trimming up to 30-inch widths, it features QuickMOUNT mandrels for efficient loading and increased production capacity. Types of material processed include self-adhesive vinyl film, vehicle wrap film, magnetic film, banner material, photo paper, wallpaper, and mesh. According to the company, the converting system offers a productivity gain of over 40 percent compared to analog methods.

Convert Away

Not a new or complex technology by any means, converting equipment—both roll slitting and rewinding—is another step in the process to fully automate a PSP’s production workflow. Adding a log slitter into a wide format print operation controls inventory and material waste. It’s another level of efficiency to streamline a business.

Jul2018, Digital Output