By Melissa Donovan

Boosting business can be as simple as investing in a desktop or tabletop device. These multi-faceted, smaller format printers present endless application opportunities.

Recently, there’s been buzz surrounding digital printers used in the production of ADA and braille signage. Like most applications that are traditionally manufactured via more manual methods, ADA and braille signage benefits from digital printing’s speed, productivity, and efficiency.

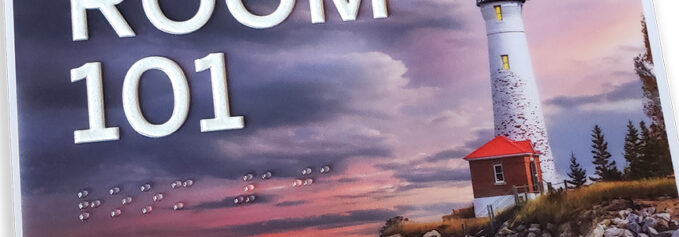

Above: Mutoh UV desktop/tabletop flatbed printers include the software necessary to produce durable, high quality, and legally compliant ADA and braille signage.

Top Influences

Digital desktop/tabletop flatbed printers influence the modern production of ADA and braille signage.

“Digital printers introduced a paradigm shift in the manufacture of ADA signage. The reduction in steps affects labor and costs and allows additional creative approaches,” attests Kevin Currier, director of marketing, Direct Color Systems (DCS).

Hugo Gonzalez, senior segment specialist, IP, Mimaki USA, Inc., agrees. “The small format flatbed printer industry greatly influenced the production of ADA braille signage. It significantly reduces the amount of operator input required to make a single sign. Printing braille and ADA signage can all be done on one machine while handling the material once and printing multiple copies per setup. This also frees up the operator during printing.”

A digital printer’s ability to jet layers for texture is another advantage. “ADA-compliant signs can be recognized by texture as well as color, so color blind people can read and visual blind people also can touch braille. One of the easiest ways is to use layered UV inkjet printing to make these signs,” shares Juan Kim, CEO, Valloy Incorporated.

Emilio Rangel, UV desktop product manager, Mutoh America, Inc., says methods of producing ADA-compliant braille signs include braille raster beads, etching, thermoforming, or photopolymer. These involve additional steps to create the braille dots, tactile elements, and text required for compliancy.

Another traditional braille production method is routing, which also requires multiple steps and longer production times, says Currier. “Digital provides an additive process that is fast to setup and easily reproduced later without any inconsistencies.”

Without digital printing, the production of ADA signage is manually intensive. An operator needs to handle each piece and be present at every step of the process. “In traditional methods, many steps require an operator to handle the material one piece at a time to perform tasks like adhering materials, routing, drilling, and placing beads all on different pieces of equipment,” explains Gonzalez.

Feature Time

Enhanced/new features on recent desktop/tabletop printer introductions focus on increased quality and layered printing.

“Increased printing quality and layered printing techniques play a vital role in creating ADA braille signage that is legible, durable, compliant, and accessible to individuals with visual impairments. Without layered printing, ADA-compliant braille is not possible to produce on a digital printer,” explains Rangel.

Layered printing is specifically of interest in architectural signage, according to Currier. DCS’ series of flatbeds offer the ability to create functional ADA complaint signage combined with imagery and decoration due to layering.

Kim cautions on the challenges involved with layered printing. “If you use the same speed, resolution, and jetting amount for textures and colors, you print too many layers with too many passes. To reduce the production time, there needs to be a control for fewer passes and resolution with a larger amount of drops during texture printing before high-resolution color printing. In this way production time can be reduced.”

Other features are important to note. Kim brings up software and how it is integral in the process of slicing layers for fast production to create a semi three-dimensional effect accurately.

Get Involved

For a wide format graphics shop unfamiliar with ADA and braille signage, leveraging existing, familiar technology makes sense.

Taking on printing of ADA and braille signage expands the portfolio variety of a business. “It allows a shop to offer customization and include embossed and textured effects to logos and images that can be printed simultaneously with little or no additional required time. Additionally, the range of high contrast colors is no longer limited by available materials,” explains Gonzalez.

This type of work is complementary to many of the projects already offered. “A graphics provider should consider the advantages of being able to take on a construction or wayfinding project in its entirety. ADA signage can be offered as an additional job, keeping it in house and ensuring consistency across the project,” says Currier.

“When those unfamiliar with ADA see the capabilities of the printer, the profits to be made, and the ease of use, it will be quite clear how expanding offerings to existing clients can lead to increased profits,” attests Rangel.

Into It

With enhanced software features, layered printing, productivity, and high quality, utilizing digital printing for ADA and braille signage makes sense.

“Digital desktop/tabletop flatbed printers are revolutionizing the production of ADA and braille signage, offering improved efficiency, design flexibility, cost effectiveness, and versatility. These advancements empower sign makers to efficiently create high-quality, compliant signage,” states Gonzalez.

As awareness of digital print in this space spreads, it won’t be surprising to see traditional methods of production dissipate in favor of digital print.

Sep2023, Digital Output