By Cassandra Balentine

Some wide format applications, like banner stands, benefit from double-sided printing capability. Like its name implies, double-sided printing allows the display of an advertisement or a message on both sides of media. The feature is necessary for certain applications, including double-sided pop-up, roll-up, or pole banners. It offers many benefits including reduced waste and materials. Luckily, several wide format printers offer this as a standard or optional feature.

“In its basic application, double-sided printing allows for viewing a sign on both sides. If it’s a banner or multi-layered window graphic the final result allows the customer to display an advertisement and have it be viewed from the front and back, essentially doubling the exposure,” shares Larry D’Amico, sales director, Durst Image Technology US, LLC.

Tom Wittenberg, large format industry relations and events, North America, HP Inc., says double-sided writing capability cuts the time and ultimately the cost to produce this type of banner, thereby allowing the product to reach the market at both a lower turn time and minimized cost.

“Double-sided printing adds value to customers and increases the range of applications a print provider can offer to their clients,” shares Mike Kyritsi, president, swissQprint America. System features, like high-resolution cameras in combination with quick response (QR) codes, help to ensure accurate alignment, which minimizes downtime and wasted material.

Bill Brouhle, solutions architect, Agfa, adds that double-sided printing is also environmentally friendly, using less substrate while at the same time minimizing the cost of manufacturing and shipping.

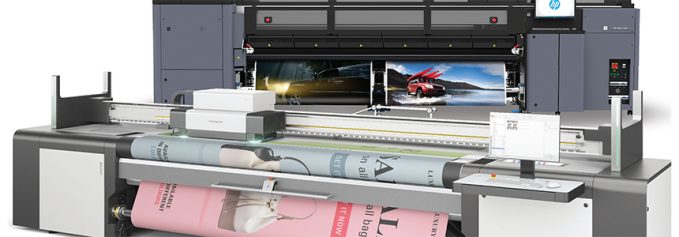

Above: The HP Latex 3600 Printer offers double-sided roll capabilities; as does the HP Latex 365 and HP Latex 1500 Printers. The swissQprint Karibu was launched in 2019, the Karibu S as well as the double-sided printing option were introduced in 2021. The optional feature can be upgraded in the field at any time.

Double Trouble?

When implementing double-sided printing on capable devices, print service providers (PSPs) should keep in mind certain considerations and challenges, including registration as well as color management.

“Traditionally, the most challenging part of double-sided printing is registering the front and back sides of the print but as a camera system reads the QR codes automatically, there is no special operating skill required,” admits Kyritsi.

“As with any type of automation, it needs to be kept in tip-top running condition. Without this, it becomes very difficult to manage the registration, both front and back,” cautions Wittenberg. In his experience, registration is key and if you’re not paying attention, it can become a problem.

“Imaging these types of displays can become complex,” agrees D’Amico. He says beyond the basic front-to-back registration, some applications that rely on clear substrates, like window graphics for example, can require as many as five layers. For instance, certain applications may call for layers of color, white, black, white, color.

John David Kaufman, specialist, marketing senior, LFS marketing, Canon Solutions America, says users can overcome color accuracy and alignment challenges by using LED cold curing, which does not apply any heat. “This allows for precise front-to-back lineup because the media is not distorted by the extreme heat of other technologies.”

He says Canon’s UVgel inks also help overcome registration and color issues on double-sided prints. “The Colorado’s UVgel inks are a gel, not a liquid ink. The gel inks have no coalescence and our colors do not muddy up with the excessive dot gain that other technologies in the market have with a liquid form of ink.”

Brouhle points out that some substrates will present challenges. “Some materials are cheaper, and inconsistencies and quality control issues can be harmful us. With Agfa’s closed-loop manufacturing systems approach, we manufacture, integrate, and optimize our engine, ink, media, workflow, and color management to ensure the highest quality, consistency, and reliability for our customers to help them eliminate as many production challenges as possible.”

Open Opportunities

There are several occasions for PSPs to implement double-sided printing.

For example, Brouhle says the Agfa Jeti Tauro H3300 LED with master roll to roll helps provide long-run, roll-to-roll jobs as well as roll-to-sheet work, enabling fast throughput and hardly any material waste.

Kaufman notes that posters are among the most common opportunities for double-sided work in the wide format market, especially on heavier machine paper and styrene, double-sided pop-up, roll-up, and pole banners. “There may be some specialty applications out there that require gluing, cutting marks, or labels, but we haven’t seen much of a demand for that in the 64-inch market space. These are common applications that you can find in any retail, restaurant, educational environment, and many other public spaces, including hospitals and more. Gas station pump toppers is another great application.”

D’Amico points out that double-sided applications have been utilized for many years. Silicone edge graphics (SEG), in particular, is a growing segment in the market. The use of UV inks for SEG provides better contrast and density on backlit graphics.

In addition to opportunities, print providers should explore the ability to do more with double-sided printing capabilities.

“While not a huge opportunity, the capability can be used for double-sided backlits for indoor and outdoor use. Namely, transportation signage, mall signage, and advertising,” shares Wittenberg.

Kyritsi adds that double-sided printing can be used to create day/night backlit prints on both paper and fabric without having to print white since the media works as the blockout layer.

Brouhle sees a myriad of media and print applications where the Agfa Jeti Tauro H3300 LED excels. “It is ideally suited for producing banners, posters, folding carton corrugated, exhibit graphics, point of purchase, mockups, backlit, front lit, and self adhesives. And with the master roll-to-roll configuration you can print on rolls of substrate that can be up to 23.6 inches in diameter and up to 1,500 pounds per roll.”

D’Amico points to the use of window graphics on clear materials as a growing segment. “This may create some complex multi-layered output requirements but also represents improved profit opportunity.”

Solutions

Several wide format printers offer double-sided printing capabilities.

The Agfa Jeti Tauro H3300 LED with master roll to roll builds on decades of experience in developing and manufacturing versatile large format printing solutions. In the Jeti Tauro H3300 LED printers, users find heavy-duty workhorses designed to easily handle extreme workloads, multiple-shift operation, and 24/7 printing. Suited for a variety of rigid and flexible substrates, these printers offer many options to create eye-catching, large format prints. They can be deployed in six configurations with different automation options and in 2021 the company released the double-sided camera option to the master roll-to-roll configuration.

Double-sided printing has been a standard feature on the Canon Colorado 1650 since its launch in June of 2019, and it became available as a standard feature through a modification kit and firmware upgrade for all the Colorado 1640 users later that year. However, Canon decided to make this an optional feature in its latest model in the UVgel line up, the Canon Colorado 1630, which was launched in May 2021.

The Colorado 1630 is a modular system where users only purchase the options needed. There are two models in the line up, the 1630 Standard and the 1630 Deluxe. “The Colorado 1630 Standard model has all the automation, the same robust build, and all the industry certifications of the Colorado 1650. It produces gloss production only, has one ‘Active’ roll position in the dual roll media drawer, print side out only, and it produces single-sided production,” explains Kaufman.

He says the Colorado 1630 Deluxe model has all the features of the standard model, plus matte/gloss FLXfinish, two active rolls in the dual roll media drawer, the availability to print double-sided applications, and the feature of printing on print side in or out materials.

“The beauty of these options is that they are all license based; so, there is no need for a service intervention or hardware upgrade. It is just a flip of a switch,” adds Kaufman.

In dedicated roll products, Durst offers the Rho 312R and Rho 512R. “These roll-to-roll printers are known for their speed, quality, and reliability. We also offer the P5 350 and P5 350 HS. These are 3.5-meter hybrid printers that provide excellent results for roll-to-roll applications,” says D’Amico. Double-sided printing is an option on the presses.

The HP printers with double-sided roll capabilities are the HP Latex 365 Printer, the HP Latex 1500 Printer, and the HP Latex 3600 Printer. “The capability was introduced a number of years ago, so the automation is tried and true and was carried over to the current models mentioned,” shares Wittenberg. All of the printers with the capability have it as a standard feature.

The swissQprint roll-to-roll printers Karibu and Karibu S may both be equipped with the double-sided printing option. The Karibu was launched in 2019, the Karibu S as well as the double-sided printing option were introduced in 2021. The optional feature can be upgraded in the field at any time.

How it Works

Understanding what makes a printer tick reduces challenges and expands options.

“Double-sided printing is handled with sensors that read a mark on the back side and automatically make adjustments to position the image and ensure back-to-back accuracy,” explains D’Amico.

According to D’Amico, “the sensors are essential, but if your printer does not track media accurately you will struggle with back-to-back repeatability. The tension control and roll adjustments provide highly accurate back-to-back printing, in many cases with no operator intervention.”

Kaufman says when performing any double-sided printing the proper double-sided media must be used for the application; for example, double-sided blockout vinyl banner materials. “If your substrate is only intended for single-sided printing, then your quality will not meet the market standards; in addition, you may end up with equipment issues, printhead strikes, and ink adhesion problems.”

Once the correct media is settled on for the application, the next step when using a Canon Colorado device is to establish the desired print mode to ensure that the Enhanced Automatic Advance Correction (AAC) markers are enabled. Next, ensure the layout is centered so that the two images will align from side to side. In addition, make sure the layout allows for a one-inch margin on either side of the print to allow for the placement of the AAC markers.

“If you need finishing marks, you will also need to allow additional space for these, and your print file should also include bleed to ensure registration. We recommend, when possible, that you run your jobs vertically in the unwind direction to allow for the grain of the substrate to remain in its natural state. This may not play out in all cases depending on the size and layout,” adds Kaufman.

Users should then place a measurable leader on the beginning of a print. “Once the initial side is printed you want to mimic this amount on the second surface. This enables registration of prints from top to bottom. The artwork should be rotated accordingly for the second surface,” he explains.

Be aware of the length of the roll to make sure your number of copies does not exceed that measurement. “You do not want to surpass the printable area of the roll, as the media is more than likely taped or glued to the core and will cause an emergency stop in the system and your project will not be recoverable,” cautions Kaufman.

Color is subjective. To minimize any issues, Kaufman suggests taking care to employ the same color management to both sides of the print. “An easy way to keep track of this is to enable printable notes in your RIP settings, so that relevant data is printed below the artwork. This can then be referenced when printing on the second surface.”

To produce a double-sided print using the swissQprint Karibu, Kyritsi says the operator prepares a multi-page file, specifies the front and the back sides in the RIP, and then sends it to the output software, Lory. This is where the print settings are defined. “Lory automatically adds a series of QR codes to the lead and tail of the images. The codes are printed with the images. They tell the system which file is needed to back up as well as the positioning and orientation of the front side image. This is key to precise double-sided printing.”

Once the front side of the roll is printed, Kyritsi says it may either be rewound or cut off and then reinserted on the intake side of the printer again. Once the roll is reloaded with the printed side faced down, the print start is triggered and the machine will begin to advance the media over the camera until it finds a QR code. This tells the printer which back side needs to be printed as well as the position and orientation. Production continues on from here until the back side of the roll is complete as well.

Brouhle says that when utilizing double-sided printing, optional back-to-front cameras facilitate smooth double-sided printing in either single- or dual-roll printing configurations. “This is a very well thought out design whereby the double-sided option is enabled in the press graphical user interface. The Agfa Jeti Tauro H3300 LED with master roll to roll will automatically apply the appropriate QR codes to side one of the already RIPped files that are about to be printed. These QR codes are repeatedly printed along the edges of the first side of the master roll to roll. After the completion of the first side of roll printing the rolls are flipped and reloaded for side two printing. The QR codes, when read by the built-in cameras, will automatically tell the press where to print side two, using the location metadata stored within the QR code. This is all done live as side two is being printed so that they are in perfect registration to side one. Even if the press is stopped or interrupted in the middle of a job when printing side two of the press can resume and pick right back up from where it left off.”

Double-Sided Success

Many wide format printers offer standard or optional double-sided printing capabilities. From banner stands and window graphics and backlit solutions, this feature helps expand opportunity. However, during implementation, color management and alignment are critical considerations. Most of today’s wide format printers are equipped with the correct tools to help print providers succeed in executing double-sided printing.

Oct2021, Digital Output