By Cassandra Balentine

Print service providers (PSPs) are tasked with supporting a range of applications, from short-term banner displays to high-quality décor graphics. For many, it means honing in on experience to come out on top, no matter what the job may entail.

Established in 1996, Source One Digital is a full-service grand format digital printing company. Its core service offerings include graphic design, printing, finishing, and installation of custom graphics. The shop is G7 Master Certified and provides a range of work for nationwide clients, including point of purchase (POP), sports, events, permanent interior décor, branding, and museum and exhibition graphics.

Source One Digital is headquartered out of a 25,000 square foot production facility in Norton Shores, MI. The company also operates other storage and warehouse facilities in the area, as well as a sales office in Grand Rapids, MI. It employs a staff of 60.

The company provides full-service digital printing, specializing in the latest grand format solvent, UV flatbed printing, digital finishing, and direct-to-fabric sublimation printing. “We are dedicated towards top-notch customer service using our team of industry specialists and advanced technology in digital printing,” note Randy Crow, CEO; Jim Freed, VP; and Katie Jasmin, VP of national sales, Source One Digital.

The company’s client base and core offerings are diverse. For retail and brands it develops and produces POP signage products and displays. In sports, staging, and events miles of mesh banners and sponsor signage is produced. For the wholesale industry, it is a resource for large volume flatbed digital printing, white ink, dye sublimation (dye-sub) fabric printing, shape router and cutting capabilities, and lamination.

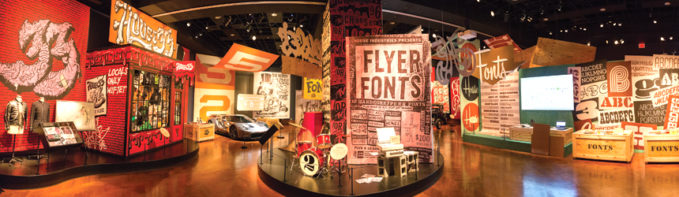

Above: Norton Shores, MI-based Source One Digital utilized all of its digital print and finishing resources to create graphics for House Industries’ 10,000 square foot exhibit.

The Road to Digital

The family-owned company is rooted in the advertising business. In 1981, Randy Crow operated an advertising agency known as RC Productions, as it grew, the demand for quality signage grew with it. At this time, Crow realized many companies struggled to find a resource to produce the level of quality it needed, and from there, hooked up with print provider, Signs by Jim. Source One Digital founders Crow and Freed decided to open Source One Digital.

Signs by Jim was a traditional sign shop, but after the acquisition from RC Productions, digital print capabilities were added to expand the business. “We have a large array of the latest digital printing equipment. Our goal is to service our clients with complete digital grand format needs,” explain Crow, Freed, and Jasmin.

To do this, it operates multiple UV roll-to-roll printers up to 16 feet wide, which include latex and white ink capabilities. It also utilizes UV flatbed printers with white ink, and these include both high-speed and fine art quality machines to allow every job to meet a diverse set of needs. It also employs short-run solvent photographic printers. “We try to have the right tool for every type of job,” they comment.

“It’s exciting to know that we never have to compromise quality,” says Crow. “We have the right equipment to provide the best solution for each job.”

In addition to a range of printers, finishing is essential. Source One Digital’s finishing lineup includes multiple routers and Zünd machines with beds up to ten feet. It also operates a 50-foot Miller Weldmaster Corp. welder and its own in-house sewing capabilities, including the ability to produce silicone edge graphics frames.

For workflow, the PSP looks to both Caldera and Onyx Graphics, Inc. production software. A custom software program, Job Tracker, enables the company to follow an order from end to end and communicate product details.

Museum Work

Source One Digital recently completed a job for repeat customer, House Industries. According to the company, this client is known worldwide for its eclectic font collections and far reaching creative exploits. House Industries has worked with a diverse list of collaborators including the estate of Charles and Ray Eames, Heath Ceramics, Hermes, Jimmy Kimmel, John Mayer, Muji, and The New Yorker.

Additionally, House Industries’ work is found in the permanent collection of the Cooper Hewitt, Smithsonian Design Museum in New York, NY. It was the subject of a major exhibition for The Henry Ford museum in Dearborn, MI this past Summer.

For House Industries’ The Henry Ford museum exhibit, Source One Digital showcased its diverse portfolio of capabilities in large format print production of fabrics, plastics, wood, and metal. House Industries’ 10,000 square foot exhibit, A Type of Learning, was in residence from May to September 2017.

David Dodde, one of the lead curators at House Industries has been working with Source One Digital for nearly a decade. “Dodde is first and foremost an artist and continually pushed the envelope to ask us to bring his quirky and eye-catching designs to life,” share Crow, Freed, and Jasmin.

“Dodde was one of the first clients to challenge us to print UV direct onto wood veneer to make custom printed furniture,” says Jasmin. “He had us print 20×20-foot ceiling murals that were album cover art from the 70s direct to the prefabricated ceiling tiles he provided for a bar restaurant chain he designs for. He has had us print onto table tops that were then laminated and used commercially as well,” she adds.

When Dodde and Source One Digital first discussed The Henry Ford exhibit, they quickly realized it was a great opportunity to work on a creative project that would showcase and use nearly every piece of equipment the PSP had for one job. “It was really a complete showcase piece for us to partner as their vendor and a testimony to the creative geniuses at House Industries for their design talent,” comments Jasmin.

The exhibit primarily features a combination of digital and dye-sub fabric was used to create hanging scrims that drape the walls. A poplin blend material was directly printed on a Fujifilm North American Corporation Uvistar printer. Dye-sub work was completed on a polyester blend using PrinterEvolution’s Eos126 printer. The shop also wrapped a mock house structure with 3M Commercial Solutions’ 3M Controltac Series 180C.

The client is fond of the direct print to wood look, so the entrance piece used 3D life-sized 5×5-foot old school alphabet blocks. Grayscale and white ink were used to print on optically clear films to create mylar-looking sketch paper. Dimensional objects were routed and painted with PVC foamboards and aluminum composite panels. A lot of styrene and other vinyl adhesives were also used on some of the collage work in the exhibit vignettes.

Solutions Provider

Source One Digital offers a range of printing services for the industry as well as directly to customers. Its goal as a company is to provide more than just traditional print. It is a solutions-based, experienced team of digital print and creative providers.

In addition to providing creative, output, and installation services, the PSP offers extensive knowledge gathered throughout years of practical industry experience. Its work for House Industries showcased these skills while meeting the demands of a longtime client.

Sep2017, Digital Output