By Melissa Donovan

Physically, printheads are a small part of an overall print device. However, they are a critical component. Printhead technology improvements expand digital print into new markets and as a result increase business opportunity. Achievements in grayscale capability, durability, and ink recirculation make it possible for print service providers (PSPs) to reach segments previously served by analog technology.

Flexibility Yields Productivity

Printhead changes advance wide format technologies effecting print quality and meeting PSPs’ demands for higher resolutions at faster speeds. Flexibility is enhanced as newer printheads work with multiple ink sets and feature diverse drop sizes. The result is increased productivity across the board from the production shop to the sales floor.

“By addressing a multitude of market demands such as high speed and high resolution printing, equipment downsizing, cost reduction, and reduced environmental impact, printhead technologies expand the possibilities of digital printing including wide format,” admits Sumio Arima, senior manager, IPD sales department, corporate printing device group, Kyocera Corporation.

According to Becky McConnell, product marketing manager, Fujifilm North America Corporation, Graphic Systems Division, printhead technology advances allow print quality to increase while simultaneously giving print providers more flexibility in their output.

This is in response to industry demand for faster, better, and cheaper, says Tim Rosario, senior program manager, Fujifilm Dimatix, Inc. “As a result, printheads are introduced that are compatible with many new ink sets, higher native resolutions, and faster print speeds that are easier to integrate,” he continues. Fujifilm offers two-color printheads that allow system designers to pack four colors into a very small carriage while also maintaining productivity and quality, adds Rosario.

Flexibility is associated with drop sizes, which Akihisa Maruyama, inkjet business unit, Konica Minolta, Inc., suggests is important and effective for matching customers’ quality needs. “Our proprietary ink injection control technology has reached a new level that allows flexible ink adjustments for diverse drop sizes,” he explains.

Esteban Marin, director – Printek division, Seiko Instruments USA, Inc., believes that current printhead developments focus on providing three major technological breakthroughs and that all major original equipment manufacturers (OEMs) adopt printhead technologies that provide one or all. These are water-based compatibility such as latex-type developments, nozzle redundancy to yield print quality reliability, and reliability in general to reduce ink waste.

The stability of today’s printheads increase productivity. “Printhead technology advancements also allow for some printheads to be more durable. This makes for easier press maintenance, which makes operators more productive. Also, with easier maintenance comes increased uptime,” explains McConnell.

Go with the Flow

PSPs expect high image quality and productivity at low running costs from their printers. Today’s printheads help them achieve this with recirculation features that control ink flow.

According to Marin, most printhead suppliers during 2014 to 2015 focused on launching higher resolution printheads with recirculation. He cites these as two key features that result in increased printing periods and decreased probability of failed nozzles when combined.

“The addition of non-wetting coatings and ink recirculation reduces ink consumption for printer start up and reduces the need for maintenance during the day, increasing printer productivity and reducing ink waste. This also enables a variety of new and difficult inks to work in an inkjet environment,” says Rosario.

Kyocera’s printheads deliver high-quality, high-speed printing through ultra-high precision ink discharge, which is made possible by the company’s proprietary technologies in fluid channel structure design and piezo-actuator drive control. “Using the piezoelectric effect to control ink flow, the actuator is a critical component to enabling the printhead to offer high-speed, high-resolution printing,” explains Arima.

Printhead Life

New printheads come to market and actively increase productivity in print shops. Manufacturers make a point to integrate feature sets that prolong the life of this integral part of the printer. Common components include nozzle plates, side guards, and filters.

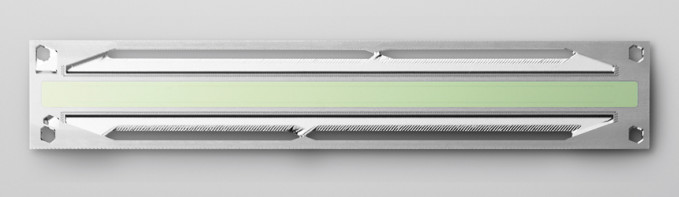

For example, Kyocera’s latest printhead for textile printing features a rigid metal nozzle plate, side guards with enhanced shock resistance, and a protected structure to prevent invasion of ink mist. “We believe that the durability achieved by these features contributes to enhanced longevity,” explains Arima.

According to the company, ink mist generated during the printing process is prevented from entering the printhead thanks to sealant applied around the connection parts utilized for making interface connections. The side guards and rigid metal nozzle plate underwent drop and shock tests five to ten times stronger compared to impact caused when fabric strikes the printhead and nozzle plate during typical textile printing, backing up the intent of the manufacturer to offer a durable design.

“Printhead life is generally affected by dirt, damage during printing, ink getting into the wrong places, or electrical issues caused from an external source,” says Rosario. Fujifilm printheads feature either metal or silicon nozzle plates making them durable and less susceptible to damage during printing. They also include an internal filter to help extend printhead life by collecting dirt. In addition, the printheads are either sealed with a conformal coating or have a cover to prevent damage from ink spills.

It isn’t just the printhead and its components that help prolong its life. “This is a combined effort not only from the printhead suppliers but also the ink companies. With less aggressive and better formulations, less maintenance is required. Maintenance is one of the processes where most user mistakes happen,” cautions Marin.

The printhead, ink, and the printer all work together. “Press features allow for increased printhead life like UV sensors and automated printhead maintenance, as well as monitoring that helps the operator know how to maintain the printheads to avoid quality degradation,” adds McConnell.

Newest Technology

The newest printhead technology features components that enhance productivity in printers.

Epson’s PrecisionCore technology is highly scalable, for use in products ranging from desktop printers to industrial systems. The modularity allows PrecisionCore print chips to be arrayed in both moving serial printhead and fixed linehead configurations. According to the company, PrecisionCore printhead nozzles can deliver drops as small as 1.5 picoliters or as large as drops of up to 32.5 picoliters.

Fujifilm builds on the strengths of its Galaxy and Nova printhead lines with new products that include non-wetting coatings and ink recirculation. It recently introduced a micro electro mechanical (MEMS) 1,200 dpi printhead for true industrial applications. Its Samba product is the basis for sheet-fed inkjet printers used in the commercial print space and is now being integrated into other commercial print applications like textiles, packaging, and label presses.

Hewlett-Packard (HP) announced the HP PageWide XL family in 2015, utilizing the HP 841 PageWide XL Printhead. This printhead prints four colors of ink with 6,336 nozzles per color at 1,200 nozzles per inch for a total of 25,344 nozzles on each printhead. Eight of these printheads are used to deliver a 40-inch print swath on HP PageWide XL large format graphics printers. HP PageWide Printheads are built using HP Scalable Printing Technology that employs common design and manufacturing processing based on integrated circuit technologies, enabling HP PageWide Printheads to power HP solutions ranging from business printing to large format and commercial printing.

Konica Minolta’s newest printhead technology was highlighted in July 2015 with plans to begin mass production in Spring 2016. Three industrial inkjet printheads—ME130H, MC160H, and ML160H—adopt Konica Minolta’s independently developed MEMS technologies, which enable 1,024 nozzles to be arrayed three dimensionally in high density. The new printheads feature improved resistance with inks, ranging from aqueous to UV and solvent, and are compatible with every industrial ink.

Kyocera launched the KJ4B-0300-G06DS printhead for textile printing in November 2015. Compatible with water-based inks, the design enhanced the printheads for use under the harsh conditions of textile printing. It offers simultaneous two-color printing with one printhead and features an effective print width of approximately four inches. The printhead can withstand temperatures between -20 to 80 degrees Celsius and operates even when dipped in high-temperature reactive ink.

Ricoh Americas Corporation uses its Ricoh Gen5 printheads in the Ricoh Pro L4130/L4160 wide format printers. Each of two piezo printheads are configured with 1,280 nozzles per head to ensure high print speeds at high quality—a precise drop is dispensed at the exact location every time, according to the company. With multi-jetting capabilities, three drops of various sizes are simultaneously applied to accommodate varying media in addition to density requirements.

Seiko’s latest printhead development is the RC1536. It is an industrial printhead developed for single-pass applications. Its unique nozzle level recirculation feature allows OEMs to utilize highly pigmented inks. The self recovery feature enables long-term sustainability by allowing drop-out nozzles caused by air bubbles or dust to recover automatically. The RC1536 has 1,536 active nozzles with a drop volume of 13 to 100 picoliters dependent on the ink and ink supply system in use.

Xaar announced the Xaar 501 series of printheads in 2014. With TF Technology in new Pulsed mode, printers can output high viscosity or heavily pigmented inks like white—the mode allows ink to be recirculated directly past the back of the nozzle only when the printhead is not jetting. PrecisionPlus architecture optimizes the actuator performance giving more uniform drop formation across the print swath. The Xaar 501 is designed to be compatible with a range of oil and UV-curable inks.

Integral Parts

Printheads expand the possibilities of wide format with features that enhance quality and flexibility. Between elements like plates and side guards and ink recirculation systems, PSPs are given the opportunity to increase productivity in their shops.

Mar2016, Digital Output