By Elizabeth Quirk

Magnets are prevalent in today’s print shops. Their allure is in the ease of use for the user, specifically during the initial install and the ability to easily change out graphics afterwards. There are two options when it comes to magnets—magnetic and magnetic-receptive media.

Magnetic media is printed directly while magnetized, or printed on then magnetized, whereas magnetic-receptive media works as a part of an overall magnetic display system, in which a magnetic base is installed and magnetic-receptive graphics are printed and attached to the magnet. Although magnetic-receptive sheeting is not a magnet, it adheres to the base material like a magnet to metal.

Attractive Trends

Magnetic media trends include a renewed focus on print quality and compatibility with multiple types of printers. The technology is quickly changing and improving as market demand for wider, thinner, and stronger magnet sheeting increases. As a result, printer manufacturers continue to innovate and magnet manufacturers are tasked with keeping up.

Magnetic-receptive media is gaining traction as a printable substrate used to create large format signage and interchangeable printed pieces. Market demands for wide format magnetic-receptive sheeting continues to increase as more graphics and signage producers/users learn about the advantages of magnetic-receptive sheeting.

In recent years, the use of magnetic graphics systems were trending among printers and retail merchandising designers. According to Mike Gertz, marketing manager, Master Magnetics, Inc., the main reason for using magnetic and magnetic-receptive sheeting for retail point of purchase displays, architectural/commercial wall designs, restaurant menus, and bank interest rate signs is the ability to easily change out variable information or graphic elements without having to remove the entire graphic.

Andrew Carpentier, president, Rochester Magnet Co., provides more insight to the currents trends for both types of magnets. “The market opportunities for sign and display makers are endless with printable magnetic and magnetic-receptive materials—vehicle signs, menu and attendance boards, directories, calendars, save the date cards, marketing reminders and warehouse labeling, to name a few.”

Influencers

Simplicity is the mother of invention. Magnets provide simple solutions for installation and change of message when the time comes to swap out a seasonal campaign or drive a promotion. Designers of point of sale displays understand that keeping it simple for the retailer is key. Carpentier argues that wide format material is now influencing the use of printable flexible magnetic and magnetic-receptive materials.

“The largest influence on the use of magnetic and magnetic-receptive materials is the ability to print the material using most print methods in the print industry today,” explains Stephen S. McLevey, customer service and product manager, Flexmag Industries, Inc., a division of Arnold Magnetic Technologies.

Jim Cirigliano, marketing manager, Magnum Magnetics Corporation, says that customer demand for outstanding imaging on printed magnet drives the market to provide excellent and consistent quality. As magnetic media’s usage for large format, high-end applications grows, product quality is increasingly under the microscope. Retailers using magnetic signage expect graphics to be crisp and flawless, so printers demand media that prints cleanly and consistent.

“Customer knowledge and interest in magnetic graphics systems as well as the increased prevalence of wide format printers drive demand for wider and thinner printable magnetic-receptive media used to create these interchangeable displays,” states Cirigliano.

Retail merchandising designers, retailers, interior designers, and most importantly, commercial printers that are knowledgeable about the advantages are big influencers. According to Gertz, the need for frequently changing information and easily interchangeable graphics for new attention-grabbing messaging has influenced this trend as well. “Comparisons of other signage and display options show that magnetic graphic systems provide an effective and economical solution,” he adds.

There are many benefits in using magnetic-receptive media in applications such as in-store graphics and large format signage that are replaced often. As more print providers and signage customers learn of these benefits, they use magnetic and magnetic-receptive media over other conventional print substrates.

For the most part, the specific application dictates the best graphic choice. According to Clay Reierson, project manager, Xcel Products, Inc., the size of the graphic, existing fixtures and displays, indoor/outdoor environment, and the amount of required change outs plus the total budget are all considerations in order to determine the course of action.

“Magnetic and magnetic-receptive media are a great investment. They are both cost effective to change, retailers are opting to keep their brands fresh. Changing these out more often helps the sale of their products and keeps them coming back to the printer for more graphics,” adds Reierson.

Alice Martin, director of marketing, Adams Magnetic Products, lists benefits including ease of installation, media portability, layered add-on messaging, and graphic cost/flexibility. Layered add-on messaging is especially attractive. “Now for both seasonal customers, or applications where a subliminal message is needed, the user can layer a 30 percent discount sign on top of existing graphics or layer key messages about a product on a daily basis,” she shares.

Environments and Applications

Both magnetic and magnetic-receptive media are ideal for temporary signage and can be removed or replaced quickly and easily, requiring no professional installers. According to Darrell Adams, VP – North America, Newlife Magnetics LLC, this makes both ideal for in-store personnel to install and for chain stores to change in-store advertising and graphics more often—at a lower cost than other conventional printable substrates.

Adams discusses both types of magnets, what environment and application they are best suited for and why. He begins with magnetic media, stating it is best suited for car signs, printed refrigerator magnets, and changeable outdoor signage. Magnetic media requires a metallic or metal surface for the magnet to attract to. Paints with metallic additives are available to be used on conventional drywall and other non-metallic surface applications.

“Once the paint with metallic additives is applied to the surface, a magnet sheet attracts to it just like it does to a metal surface. These may also be painted over with standard paint to make the wall or surface appear to look like any other painted surface,” says Adams.

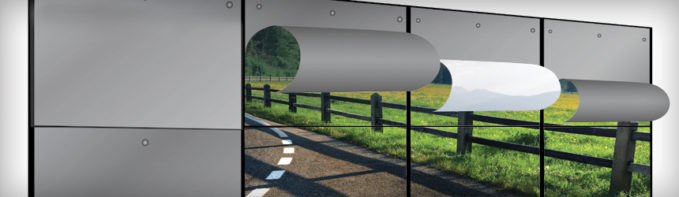

When it comes to magnetic-receptive media, Adams believes this type of sheeting is best suited for indoor use but may also be used outdoors. Magnetic-receptive media requires a standard magnet sheet for the permanent base of the application system. Once this base magnet sheet is applied to the application surface, it can be reused as many times as needed.

For permanent signage applications, a base magnet sheet with pressure-sensitive adhesive applied to the back can be used to hold the base magnet sheet to the application surface.

For applications that require complete removal without damage, a paint with metallic additives can be used to paint the wall surface so that it will attract and hold a base magnet sheet that’s been magnetized on both sides. The metallic paint can also be covered with something a little more standard to make it appear as a normal wall, according to Adams.

“The magnetic-receptive media sheeting is printed and stacked on top of the base magnet sheet that holds the receptive media in place. When changes in the printed graphics are desired, a new magnetic-receptive sheet can be printed and placed to replace the older graphic. Multiple layers of magnetic-receptive sheeting can also be stacked on top of the base magnet, which makes it an interchangeable sign that can also be rearranged to the order in which the magnetic-receptive media are stacked on the base magnet,” explains Adams.

More Magnets

Adams Magnetic Products offers MegaMAG for magnetic media. It is available in 40- and 48-inch widths and comes in 20- or 30-mil thickness. MAGbond is the company’s magnetic-receptive product. It comes in widths of 50, 54, or 60 inches in 10-mil PET or 13-mil art paper laminate. It works in combination with all flexible magnet sheet and most existing magnetic wall systems.

The Flexmag division of Arnold Magnetic Technologies offers FlexCoat-EZ magnetic material. It is compatible with eco-solvent, UV, latex, and offset ink systems. The product is available in widths up to 40 inches and thicknesses ranging from 0.015 to 0.045 inches.

Magnum Magnetics’ DigiMaxx is a superwide magnetic material. It allows users to print directly to magnet either 40 to 48 inches in width. Typical thickness is 20- or 30-mil, but custom material can be fabricated to meet specific customer requires. The material is made in the U.S.

Master Magnetics magnetic graphic system consists of PrintMagnetVinyl and FlexIRON magnetic-receptive sheeting. It ranges in cost from $1.75 to $2 per square foot. PrintMagnetVinyl is available up to 48 inches in width and printable with solvent, eco-solvent, UV, and latex printers. FlexIRON attracts many types of low-profile magnets, including flexible magnetic sheeting and strip in addition to ceramic and neodymium magnets.

Newlife Magnetics provides several components to create a complete magnet wall system. Mag-Paint is used to make a magnet stick to the wall or sign surface. Wall-Mag is magnet sheeting with adhesive on the non-magnetized side used to permanently adhere to a wall or signage surface. Ino-Steel is a printable magnetic-receptive skin that is placed on top of magnetic sheeting—up to five layers can be stacked on top of each other. DigiVinyl-Mag is a white, printable, wide format magnetic sheeting used for wall graphics placed directly on the wall painted with Mag-Paint or a metal wall/surface.

Rochester Magnet’s DigiMag Vinyl is a white, printable magnetic media for wide format solvent, eco-solvent, UV, and latex inkjet printers. The product is available in both matte and gloss finishes. When in use, DigiMag Vinyl lays flat and adheres to metal surfaces or a magnetic-receptive sheet, like the company’s RubberSteel.

Ultraflex Systems, Inc. offers Signetics Duo, printable on both sides, allowing two graphics to be printed simultaneously and changed in a matter of seconds. The double-sided capability reduces material cost, and freight and installation fees as the material is easily rolled up, turned over, and rolled back to the surface. Signetics LTX offers universal print compatibility with enhanced engineering for use with latex inks. Signetics Select is designed with a smooth backside that eliminates scratches on prints when stacked or rolled.

XMR DS, a double-sided magnetic-receptive material, is available from Xcel Products in rolls of 60 inches by 100 feet. The media is compatible with eco-solvent, latex, solvent, and UV-curable ink. Another popular product is XMR Dimensions, which combines embossing technology with a magnetic-receptive substrate. Texture options include canvas, mosaic, woodgrain, leather, and plaster.

Magnetic Popularity

Magnets are prevalent in today’s print shops. Both magnetic and magnetic-receptive media are easy to use and offer the ability to effortlessly change out graphics when needed. Although each type is best suited for specific applications and environments, both help to make the lives of retailers, designers, and many others much easier and more efficient.

July2017, Digital Output