By Melissa Donovan

Display and point of purchase (POP) signage is numerous. Options are vast when it comes to materials. Graphics can be printed on anything, from a pre-manufactured object to fabric, film, and vinyl. What was once a domain devoted to rigid substrates is now inundated with choice. Designers, brand owners, and merchandise stakeholders are presented with endless opportunities to create displays.

Rigid substrates remain prevalent. Go into any big box store and you’ll find them hanging from the ceiling, propped up at the end of an aisle, or as the actual display itself. Aluminum composite material (ACM), aluminum, rigid PVC, paper-based board, and acrylic are just some of the many types of substrates still seen in display and POP environments.

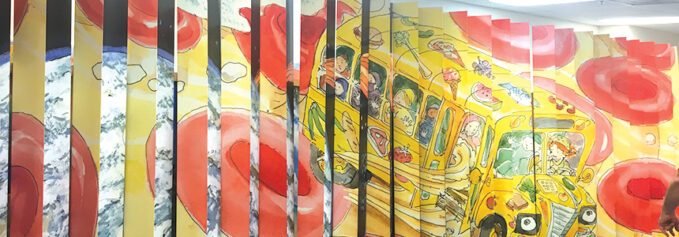

Above: Display signage printed on Duraluxe aluminum panels.

How It’s Applied

Rigid substrates are used in a number of ways in display and POP, whether purely for decoration or even as a holder of sorts. They are often chosen for their visual appearance and/or durability and structural integrity. Whether, for example a rigid PVC or ACM is chosen for the job depends on the material and application in question.

“Rigid substrates are a critical component to a successful POP campaign. They are used for greater durability, structural integrity, and ultimate visual impact. Applications range from hanging signage to structural displays capable of holding significant weight. Ever-advancing capabilities in production allow for a multitude of finishing creativity to cut, score, and fold, which makes sizing and design styles limitless,” shares Jason C. Leonard, technical sales manager, Neenah.

Common applications include posters, end caps, shelf talkers, dump bins, cut outs, banners, and signage requiring photo-quality graphics, lists Jordan Flinchum, manager, category sales Eastern U.S and Canada, ALPOLIC, a division of Mitsubishi Chemical America. “Display and POP opportunities are only limited by the designer’s imagination as long as you are aware of the types of paint and material used to make the substrate.”

“The use helps determine the material,” according to Chuck Kunze, director, product management and marketing, 3A Composites USA. For short-term campaigns, where promotions run for a few weeks or months—like Halloween or Christmas—it’s more cost effective to use a foam or recyclable paper board of some kind versus ACM or PVC, which hold up for longer periods.

“Applications where displays are needed for several months require a more durable solution, like a high-performance foamboard or PVC. Retail locations also clean signs and displays that are in reach of the customer more frequently now, so PVC and styrene products easily cleaned are being used more in those applications,” adds Kunze.

Part of what dictates usage is weight. For example, paper-based board is often used for load bearing displays, shares Rowan Maher, CMO, Xanita. “So we end up doing a lot of work for the alcohol industry as an example. They like the fact that we can offer them a significant stock holding, while still keeping the unit lightweight and flat packable,” explains Maher.

“If a display requires shelves to hold products or other heavy elements such as TV screens, the only option is rigid board. the strength of a rigid substrate is critical for POP displays holding products, lights, etc.,” adds Roberto Rodriguez, managing director, DGS – Digital Graphic Systems, Inc.

Aluminum panels offer durability, in addition to long lasting use—when needed—and the capability to be displayed outdoors. Certain products can even be bent after printing or sublimating, notes Richard Dettman, sales director, Duraluxe Inc. USA.

“ACM offers a complete option for direct digital printing, vinyl decoration, or paint to suit the exact requirements of the job. The ease and complexity of finishing with CNC makes it ideal for POP/point of sale applications. ACM is the perfect balance between weight, durability, and strength. Finished pieces can be completed and shipped flat to a job site for final assembly,” says Garrett Thompson, national sales manager, sign, graphic and OEM products, Laminators Inc.

Printable acrylic boards create eye-catching POP applications. “Acrylic separates itself from other rigid media by its high clarity, lack of color, ease of fabrication, and weatherability,” explains Chris Airoldi, product and applications development engineer, Roehm America, LLC.

Rigid PVC materials are well suited to POP and display applications, says Mike Sherrod, market development manager, signage and graphics, Vycom. “They can be formed to create dimensional and decorated store fixtures. Rigid PVC with a bright white point is an excellent fit for applications where color reproduction is essential, such as meeting customer brand color needs. For outdoor use—at a garden or lumber store, or gas station for example—their high UV resistance, durability, and impact strength characteristics are critical.”

“PVC and ACM are both easy to install, stylish, waterproof, budget friendly, low in maintenance, safe, and even recyclable. ACM can withstand higher or lower temperatures and does not delaminate or deform,” adds Flinchum.

Leonard says in most cases the application determines which material used. “Questions we urge our distributors and PSPs to ask are—is this free standing, does it hold weight, what is the desired lifespan, what is the print and finishing technology that will be used, and how will it be discarded at the end of the campaign? These qualifying questions allow for collaboration between the manufacturer and PSP to assure the most successful solution is chosen.”

All the Rage

Rigid substrates trends in connection with display and POP signage range from challenges like sourcing materials to advantages like sustainability.

Buyers are serious about the environment. “There has been a significant increase in PVC-free options. With resin shortages and significant price increases, traditional ‘green’ products are more attractive from an availability and pricing standpoint,” notes Brian Ebenger, VP of business development, Xcel Products, Inc.

“I have noticed a significant demand increase for paper-based rigid substrates because they are sustainable and companies are replacing plastic content materials with paper-based options. Some of the reasons include the convenience in logistic processes—less weight and less transportation, as well as lower costs compared to other substrates,” explains Rodriguez.

According to Bob O’Neill, national sales manager, Competitive EDGE US, manufacturer representative for Falconboard, more brands want to use sustainable—recycled content/recyclable—substrates in their POP campaigns and help get ahead of their net zero commitment. “They want their in-store graphics to have a second life by recycling their signs, displays, and POP visuals so they can align themselves with the values that more shoppers and consumers have these days.”

“Sustainable and/or recyclable materials are a macro trend that everybody is transitioning to. The nature of POP retail visual merchandising is high impact, short term, disposable displays. Sustainable solutions are critical when it is designed to be discarded after 30 or 60 days,” agrees Leonard.

Sustainability goes hand in hand with cost, according to Maher. “Cost and sustainability tend to be the biggest drivers at the moment. With paper-based board we are often approached to replace materials like MDF, ply, and metal, and it becomes a pretty easy conversation when you can offer a cost saving with the added boon of sustainability.”

A subset of the sustainability trend involves changing the open edges of paper-based rigid board. “In some cases, it is a kraft color and in others it is bright white and fluted. In the early days of corrugated structural board, people wanted to hide the edge. As branding and marketers learned the value of showcasing sustainable initiatives, it has become a desired finish to see the fluting or corrugation. It is the equivalent to highlighting a ‘printed on sustainable material’ bug on the finished product,” shares Leonard.

Products that can be reused after their initial use are attractive from a sustainable standpoint. Rigid PVC avoids landfills through programs like the Vycom Recycling Program, which is designed to take back and recycle printed and unprinted rigid PVC and acrylic sheets, as well as scraps and drops from finishing and fabricating.

Rigid substrates like wood are also eco-friendly and biodegradable, disposable in landfills, and break down over time, shares Tim Witucki, senior account manager, Panel Processing, Inc. “Recent supply chain issues in obtaining other materials and price increases on those materials have made wood products more attractive. They have somewhat held their own and so there has been an increase in this product for the POP industry.”

Acrylic substrates remain popular. Ebenger says one reason is because of their ability to provide high-quality photographic images for several brands.

“We have had an increase in the number of people asking about digitally printing onto acrylic. The use of a water-clear printable substrate is being used more to create impressive displays and signage,” agrees Airoldi.

With ACM, Thompson sees a rise in requests for metallic finishes as well as custom colors and finishes. “The metallic finishes are unique and offer an industrial look to finish displays in a bold fashion. The ability to match custom colors to maintain consistency with corporate identity and continuity across projects is key. Vivid colors and metallics add new dimension to great design and choosing the right colors and finishes create visual interest, enhance beauty, and promote a sense of balance.”

Still Applicable

With pressure-sensitive adhesive products and fabrics used more frequently in display and POP, rigid substrates are presented with competition. However, this material holds its own thanks to a combination of versatility and durability.

“There are plenty of applications like freestanding displays, wayfinding signage, and permanent displays that all require a rigid material,” says Ebenger.

Freestanding POP signs and displays eliminate the need for additional hardware and can be easily setup by store employees without the additional cost of hiring an installer, continues O’Neill.

In addition, “if you use a canvas to paint a picture you still need to buy or make a frame to put it up. With digitally printed rigid substrates your canvas is also the frame. With certain substrates like ACM, you can fabricate your printed display or POP signage into just about any shape you want,” shares Flinchum.

Versatility is another reason rigid substrates continue to be used. “There are options that can be utilized for a two-hour special event to multi-year signage or display. Materials range from extremely economical to high in price and in between. Products can be routed, thermoformed, UV resistant, or die cut,” explains Ebenger.

“They give the client a large offering to choose from. Material thicknesses can range from an eighth of an inch up to two inches thick for offerings and can be painted to match any color and machined into just about any shape. This in turn gives the client more freedom to enhance their display and make it more appealing,” adds Witucki.

Thompson points out that despite softer and flexible media being used more frequently, there will always be a need for rigid media in kiosks and shelving applications where strength and rigidity is required. “Composite panels are comprised of aluminum or vinyl sheets bonded to various high-grade cores make them strong, lightweight, and water resistant.”

“Vinyl and fabric displays can easily be damaged in daily use. Aluminum panels are extremely durable, scratch resistant, fire resistant, and bendable,” says Dettman.

We don’t think of rigid as pliable, but it is actually an attractive feature. “Rigid panels can be manipulated and fabricated into many different shapes that can provide a three-dimensional element to a display. Techniques used to fabricate and print the products have allowed producers to create exciting and dramatic displays, and the flexibility of UV or latex inks allow for post-printing fabrication without worrying about ruining the print,” shares Kunze.

The capabilities digital printing affords rigid substrates, particularly in display and POP signage, are advantageous. “Digital print allows designers to be as creative as they want when creating images for displays and signage. If a designer can imagine something, it can be printed quickly. And when printing second surface onto acrylic, the result is an impressive image with the layer of crystal clear acrylic in front of it,” shares Airoldi.

Printing directly to the board quickens the entire process. “It’s just more efficient. Post COVID-19 we’ve seen a greater need for faster turnaround times, so printing directly takes a step out of the production process and reduces production times, costs are also better managed this way,” says Maher.

Visually, digitally printed rigid substrates are professional looking to the passerby. “Brands desire to have a tangible space in a retail environment. The goal of a POP display is to proudly display a product in a highly visual and impactful way. Rigid substrates make the disposable look permanent,” notes Leonard.

Permanent Substrates

Rigid substrates remain popular for display and POP applications. There is a need for structurally integral, durable, and permanent looking displays even with the heightened demand for wallcoverings and soft signage.

Leonard finds no need to pit flexible versus rigid. “Adhesives and fabrics are additional elements that build off the structure of a rigid board display. Variable wraps, header cards, inserts, and silicone edge graphics all enhance a display. I don’t feel one replaces the other; they should be viewed as additional tools in the brand’s toolbox.”

“Simply put, there’s room for all substrates to shine in today’s market. Our industry’s most creative PSPs, exhibit houses, and fabrication studios excel in part because they find new ways of blending various types of substrates to create immersive environments. Rigid substrates will continue to perform well because our industry knows how to highlight and showcase the strengths of each substrate,” admits Sherrod.

To learn more about rigid substrates in display and POP, visit digitaloutput.net/webinars to view an archived broadcast.

Dec2022, Digital Output