By Digital Output Staff

Streamlining a print shop’s day-to-day operations enhances productivity as well as eliminates manual errors. Addressing this growing need, RIP software integrated with third-party applications (apps) like web shops, ERP, MIS, and web to print (W2P) is increasingly in demand.

“Integration is key to sharing almost real-time information between all of the software in your print shop. It is all about automation,” admits Arnaud Fabre, head of product, Caldera.

For a RIP to integrate with an app, first the developer needs to allow it, and secondly if it is allowed, it can be done in a few different ways—a proprietary application programing interface (API), a commercially available API, or a communication method designed by the software developer that works best with their RIP.

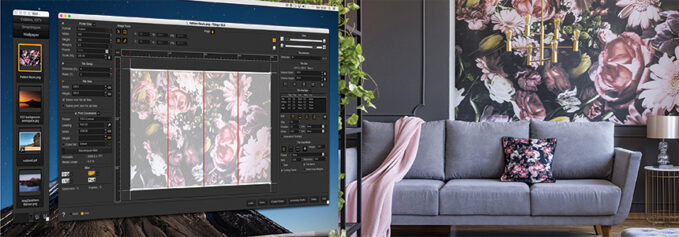

Above: Caldera recently developed its own standard REST API technology, announced in version 17 of CalderaRIP software.

Important Integration

RIPs that integrate with third-party apps increase production speed, minimize errors, and manage the entire production workflow from one integrated solution.

According to Piet De Pauw, head of marketing, Enfocus, an Esko Company, the integration of different software applications into a RIP facilitates real-time data sharing. “This allows all stakeholders, from designers to printers and clients, to have access to the latest information. Real-time collaboration improves communication and decision making throughout the entire printing process.”

“Integration is vital due to the evolving landscape of digital printing and the need for streamlined workflows. This integration allows for a more automated and efficient workflow, reducing manual input and the potential for errors. It enables print shops to manage a range of functions, from job submission and processing to tracking and reporting, within a single RIP ecosystem,” shares Brian Brooks, manager of product management, Roland DGA Corporation.

This tracks with continued interest in automation. “I think automation, or the appearance of an automated functionality, probably has a lot to do with it. The implication is that there are fewer points in the process that require an operator to ‘touch’ a job in prepress, which should translate to fewer chances for error, and greater productivity,” explains Bret Farrah, EVP, Xitron.

“Interoperability of the applications used in the shop is the key to automation, which leads to increased productivity, and reduced costs and wastage. Having invested in applications, print shops want to optimize their return on investment (ROI), and there is no better way to do this than if their applications are all working in harmony,” agrees Justin Bailey, managing director, Global Graphics Software.

According to Bennett Federico, director of marketing, SAi, “having the ability to integrate with third-party apps is not only good for software users to expand a program’s features and functionality for very specific needs, but it’s also beneficial for software developers because it can save time and money. Building and maintaining numerous integrations can be tedious and in some cases, even, redundant.”

For example, although SAi Flexi includes a RIP, it is also available as a basic design software option—Flexi DESIGN. “If someone buys a printer and it comes with its own RIP software, Flexi allows its users to output design files to that third-party RIP. This allows our product to become a part of an increasingly wider ecosystem of print and production products,” shares Federico.

“By partnering with expansive third-party apps, a RIP provider can add in-demand functionality to their platform while focusing their own development work on RIP-specific features. There’s also the learning curve to consider; many end users are becoming more educated on web tools and graphic design programs. Rather than reinventing the wheel it can be mutually beneficial to combine a professional RIP with a professional third-party tool developer,” seconds Vincent Hughes, product marketing manager, specialty production, Fiery, LLC.

“Seamless integration of design software for decorative printing—textiles, wallcoverings, flooring—with digital print output is vital due to the need for accurate previews of all aspects of output—especially color—throughout the design process,” agrees Nick Langford, chairman, AVA CAD/CAM Group Ltd.

Matt Crawford, president/CEO, Onyx Graphics, Inc., provides the concept of print service providers (PSPs) as factories. RIPs and integrated apps help connect these “factories” directly to customers, “which is fundamental for business growth and operational efficiency. This integration moves RIPs beyond being merely tools but has transformed them into comprehensive solutions that automate entire print ecosystems.”

“Additionally, the shift towards more integrated systems is a response to the growing competition through web services. Localized print services are gradually declining in favor of more comprehensive, interconnected operations. Therefore, for print shops to remain competitive and successful, embracing RIP integration with third-party apps is not only beneficial, but essential. It represents a strategic move towards a more automated, efficient, and customer-focused business model that can proactively respond to market demands and unique challenges,” continues Crawford.

Common Apps

Third-party apps that integrate with a RIP include web shops, ERP, MIS, W2P, design solutions, and much more.

While it depends on the customer and their workflow, Fabre says web shops seem to be one of the most popular apps to integrate. “Some customers feel that they do not use their equipment at 100 percent and having this new stream of order can help them to maximize profits. Still, it only has a good ROI if those jobs are highly automated as prices are tight on the web due to the existing competition of big manufacturers.”

Print shops often request integration with web stores and ERP systems, states Brooks. “These integrations allow for more streamlined workflow, where orders from web stores are directly fed into the RIP software and the ERP systems can manage inventory, invoicing, and customer data.”

Farrah says web shops and ERP are usually seen in larger size print shops, however “web stores and ERP are certainly mentioned whenever the topic comes up, but those are typically seen more in larger shops and high production environments. For smaller entities, the costs of integration are often too much to swallow and the ROI is much smaller.”

Driven by the “need to reduce production costs and enable efficient production of high-quality product in the fastest time, including the ability to invoice and get paid,” Bailey says MIS, W2P, ERP, and quality inspection systems are all regularly integrated with RIPs.

“The most common integration is with ecommerce solutions. PSPs are keen on automating the entire customer journey—from initial collection to proofing, production, and ultimately delivery. By leveraging integrated third-party apps, each of these stages can be systematically automated, resulting in a streamlined process and better overall customer experience,” explains Crawford.

Automation and ecommerce solutions are at the forefront of integrations, agrees Hughes. “It’s become even easier for entry-level production environments to grow and monetize their output. Removing barriers to entry and streamlining a workflow from orders to production to delivery has put automation and ecommerce solutions at the forefront of integrations. Having solutions in place to quickly and easily set up print-on-demand workflows has been a very popular option in the market.”

Print production tasks like preflight and proofing are two features experiencing integration. Enfocus PitStop fixes incoming files automatically and Enfocus Review proofs files online, which De Pauw says speeds up the order handling process.

Langford shares that another popular app for integration is design software for decorative printing.

API or Not

RIP solution providers update software to enable integration with third-party apps using a combination of proprietary technologies or APIs.

API can be proprietary or commercial. Caldera recently developed its own standard REST API technology, announced in version 17 of CalderaRIP software. According to Caldera, the REST API paves the way for more efficient job submission and improved job cost tracking.

This isn’t Caldera’s first attempt at developing an API. Its Nexio API offers complete JDF/JMF standard API integration. Filename-based API SmartImport automates job submission in order to fulfill the need of small shops. PrimeCenter includes a simplified XML ticket file-based API to target medium-sized shops not ready for Nexio.

Onyx utilizes standard REST API technology for Onyx Sync—a commercial API that fosters connection between ONYX Thrive and any system equipped with API connectivity. Using REST API technology was a “deliberate choice that reflects our belief in using standard technologies to facilitate extensive compatibility and ensure our customers can connect effortlessly with a range of systems,” explains Crawford.

“We have written a software module, which provides perfect integration with all printer drivers from our preferred partner—PrintFactory. AVA CAD/CAM customers can also output to RIPs from other providers using TIFF output but the integration module provides a superior user experience,” shares Langford.

Integration with third-party apps is possible without an API. Fiery’s integrations aren’t based on a standard API model. “Without an API, it’s very simple to integrate with third-party apps, although the scope may change on a case-to-case basis. By discovering potential partnerships between our RIP and third-party vendors, then working together to bring those partnerships to life, we are able to share the workload in development,” explains Hughes.

While Global Graphics does have APIs, it relies on its OPC UA approach instead. Its SmartDFE embraces OPC UA, a secure industry-standard communications protocol used in manufacturing settings.

“Unlike JDF, which is a protocol only used in pure print environments, OPC UA is used to connect to almost anything in the factory, even enabling remote access. For example, we have customers that integrate with MIS and ERP systems upstream, ink delivery systems, and downstream inspection or finishing systems, among many other interesting use cases. OPC UA is simple to implement via a OPC UA client and is an enabler for Industry 4.0 working practices,” explains Bailey.

Another example, Xitron’s Navigator DFE uses an API, but its traditional Navigator RIP and Workflow integrates apps programmatically, embedding them within the Xitron framework. “One example is our collaboration with Ultimate Technologies’ Impostrip imposition app, which is fully integrated with our Navigator workflow. Having this engine built into our workflow means that print jobs can be processed inline instead of moving a job from one app to the next,” shares Farrah.

Federico says SAi plans to have its own API in the near future. “Not having your own API makes things significantly more complicated when it comes to integrating third-party apps. In the case of SAi Flexi, it’s able to communicate with other RIPs during output but having a more sophisticated integration is very difficult or even impossible unless you have your own API.”

“Not having your own API can limit the ability of the RIP software to directly integrate with third-party apps. However, this doesn’t entirely remove the possibility of integration. In some cases, workarounds can be employed, though they may not be as efficient as direct integration via an API. The emphasis in such scenarios is placed on ensuring the highest quality and reliability of the printing process, with the software being specifically tailored to different brands and types of hardware,” agrees Brooks.

There’s also the argument for a “closed” system approach, which is something Roland offers with its VersaWorks RIP. “By maintaining a closed system, we ensure our software is optimized for our hardware, providing a seamless and efficient user experience. While this approach limits the ability to integrate with other brands, the benefits in terms of ease of use, advanced features, consistency, and integration with Roland products provides value to our end users,” shares Brooks.

Heart of the Print Shop

Streamlining and efficiency are top buzz words for PSPs. One way to achieve both is to look at the heart of your print shop—the RIP. Many solutions are able to integrate with popular third-party apps, which assist in automating a production floor from end to end.

Mar2024, Digital Output