By Melissa Donovan

Really unique, one-of-a-kind work is something that only certain print service providers (PSPs) can handle. A nimble, flexible company is ready to quickly step up when presented with a challenge. Most often, they don’t see it as a challenge, but a really fun project or another day at the office.

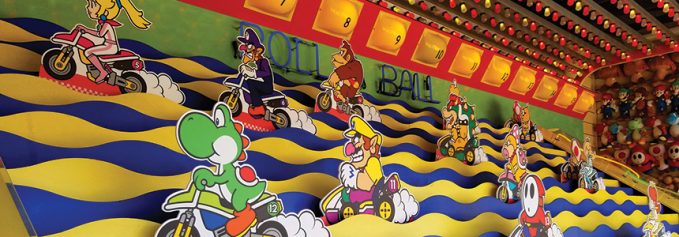

Above: Vinylbomb completed the graphics for a major theme park’s Roll-A-Ball game using a Trotec Speedy 400 and MultiCam 1000 Series CNC for the finishing aspects of the project.

Diverse Skill Set

Vinylbomb of Hamilton, NJ is one of those PSPs. Actually, don’t even refer to it as a PSP, according to Chris Rodkey, owner, Vinylbomb. “Vinylbomb as a company quit the ‘print’ business years ago. We have plenty of print and finishing equipment, but we are not just a print shop. We are so much more than that. Having that label does no justice for our diverse skill set.”

Set up as a business six years ago, the employees at Vinylbomb have 80 years of collective experience as creative designers, engineers, and makers. Its customer base is a mix of other printers, consultants, brokers, and end users.

While Rodkey admits the company specializes in “strange and unusual” projects, standardized work still gets special attention and recommendations. Every project is unique. Some examples include printing on astroturf, a laser cut and engraved ping pong paddle to scale out of mirror gold acrylic, producing graphics for an entire train station, color matching and installing exhibition work for universities and museums, rebranding games at amusement parks, and installing displays on the busiest streets in New York, NY.

Open to Options

This wide swath of diverse applications means it is almost impossible for Vinylbomb to use the same papers and substrates each day. It relies on 3M Commercial Solutions, Arlon Graphics, Avery Dennison Graphics Solutions, FLEXcon Company, Inc., General Formulations, Mactac, and ORAFOL Americas to get the job done.

Printing a variety of media requires dependable hardware. At Vinylbomb this includes an EFI VUTEk GS3250LX Pro with UltraDrop Technology for direct to substrate and white ink work, an EFI VUTEk QS2000, and two Mimaki USA, Inc. JV300-160 printers.

Cut as Fast as You Can Print

Complementing the printers are two automated finishing devices, a MultiCam 1000 Series CNC router and a Trotec Laser Speedy 400 laser cutter. “This equipment allowed us to open up a previous bottleneck. If you have printers that produce jobs faster than you can cut it’s a problem that needs to be addressed,” notes Rodkey.

The MultiCam 1000 Series CNC router finishes items such as gatorboard, magnet, coroplast, adhesive vinyl, foamboard, sign foam, MDF, plywood, packaging, larger pinmount logos, and mitering edges for plinths. It is equipped with a spindle, oscillating tool, drag knife, and creasing wheels.

When looking for ways to cut smaller acrylic letters with detail that could not be achieved on the CNC router, the company purchased the Trotec Speedy 400. It cuts through half-inch acrylic with laser polished edges.

The Trotec Speedy 400 was acquired right before COVID-19 shut everything down, so although Vinylbomb bought the device for acrylic letters, it switched gears and began making face shields from PETG and polystyrene. When demand slowed in this space, it hoped traditional business would pick up—but it didn’t right away and Rodkey realized he needed something else to create income.

“The flexibility of the Trotec Speedy 400 allowed us to create another product we call a Clockface. A Clockface is a custom clock that uses some paint and 1/8-inch plywood. We engrave the paint to reveal the wood finish and then cut through the plywood to give us a finished product,” he explains.

Both the Trotec and MultiCam are set up for print-and-cut workflows that register a six-millimeter (mm) fiducial with the onboard camera. “We add bleed to the creative, setup a cut path in Adobe Illustrator, and place the fiducials for registration with a plug-in. The Adobe Illustrator file is saved and processed with EnRoute by SA International for the MultiCam or Trotec JobControl for the Trotec,” shares Rodkey.

Amusing Work

Vinylbomb recently completed a project for a major theme park. The amusement company wanted to repurpose its Roll-A-Ball game. Vinylbomb utilized all of its equipment in house, combining print methods, substrates, fabrications, and templates.

Themed Mario Kart after the popular video game, characters were printed directly to six mm white PVC on the EFI VUTEk GS3250LX Pro and then routed on the MultiCam 1000 Series CNC router. The characters were challenging due to their placement, as the track hardware they attach to is set at an angle. “We wanted to make sure the character did not crash into sides of the game at the start or finish line. I used the Trotec laser cutter to make templates for the characters and hardware placement,” explains Rodkey.

The part of the game where balls are rolled up lanes was produced using a permanent adhesive vinyl with thick floor graphic laminate to ensure it could withstand the wear and tear of the balls placed on top. For the dividers positioned in between each lane, they are decked out in cast vinyl in a blue checkered pattern with matching lamination to ensure durability and avoid shrinkage.

Each lane also includes headers designed to be backlit at night. These were printed on the EFI VUTEk GS3250LX Pro in color, white, color. “This allowed them to look good when frontlit during the day. The additional layer of color under the white gave enough saturation to look good at night when backlit,” says Rodkey. After printing, the headers were laser cut to size on the Trotec Speedy 400 so the hardware could be properly installed through them.

Creative Thinking

The dedication of the Vinylbomb team as well as its decision to invest in not only quality wide format printers but automated finishing equipment has shaped its path in the industry.

Apr2022, Digital Output