By Digital Output Staff

Wallcoverings range from straight panels to intricate, contour cut shapes depending on the application. Finishing each type can be challenging when relying on manual practices, which is why semi-automated and automated XY cutters, static- or conveyor-based flatbed tables, and even laser devices are advantageous to any print shop with regular requests for digitally printed wallcoverings.

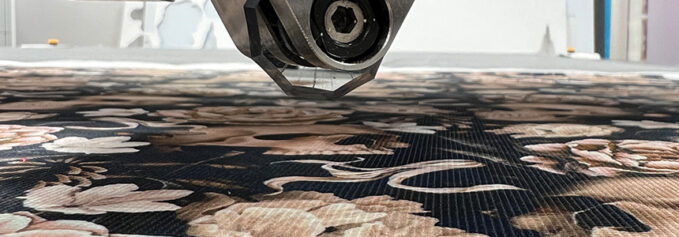

Above: Beaver Paper & Graphic Media, Inc.’s TexStyles FashionWalls is a new line of printable sublimation fabric wallcoverings that run through a calendar heat press and then cut on a Cutworx Apex Pro with a rotary cutting tool.

Accuracy Combats Challenges

Depending on the application, cutting digitally printed wallcoverings can range from fairly simple to difficult. A wallcovering that consists of multiple panels needs to be cut to the correct size to ensure proper alignment. Contour cut graphics that will eventually translate into wall decals must be consistently cut to the correct shape. Certain considerations are important to achieve these goals.

According to Chase Pender, business development, Supply55, Inc., print providers face several challenges when finishing wallcovering panels—of note are accuracy, waste, and workflow. “Precision accuracy is crucial when cutting wallcoverings to the correct size to ensure proper alignment during installation. Any inaccuracies in the cut will result in wasted material or an inferior finished product. Cutting wallpaper panels can be time consuming. Due to the print volume generally associated with them it’s important to have a workflow in place that is not only efficient but accurate.”

“Especially for cutting larger or no-bleed panels, the accuracy of the cutting machine is critical,” attests Beatrice Drury, marketing manager, Zund America, Inc.

Material deformation is another challenge. During the cutting of the wallcovering, there could be potential stretching, so the media must be carefully placed to avoid any inaccuracies, notes David Stevens, technical development manager, Trotec Laser Inc.

When it comes to wallcovering panels, space restrictions for production can be an issue. “Smaller shops may run into scenarios where they may not have adequate space to allow a 50-foot panel to run out flat from a trimming device, which is when a cutter with inline rewinding would be advantageous,” explains Raum DiVarco, GM, Cutworx USA.

Aligning and tiling panels is another consideration. “If an existing platform is not available with automatic tracking and correction, you might have trouble producing panels that line up. Tiling is another situation where there is waste in unnecessary set up time—is this process being done manually by a graphic designer or software to streamline the process,” asks DiVarco.

Fine Forms

Both XY cutters and flatbed devices are used to finish wallcoverings. Automated capabilities make them favorable, especially if the wallcovering job at hand requires a higher volume of finishing.

Of course, manual cutting is always an option. “Straight edge and sharp blade are kind of understood, but remember to keep your blade perpendicular to the cutting surface to avoid any of the unprinted core of the material showing through,” recommends Jay Kroll, product manager for cut, transit & wall solutions, General Formulations.

“Cutting panels can be done several different ways, by hand on a large cutting table with a straight edge and new sharp blade, or a built-in table cutter, which is okay for a small job. If you need speed and proficiency, there are several automated XY cutting systems with more features,” shares Steve Yarbrough, customer experience manager, Neschen Inc.

“The best option is to use an XY cutter specifically for cutting wallpaper panels. These are designed for the application and provide the cleanest cut possible,” agrees Kroll.

Automatic XY cutters are used “because of their precision, speed, versatility, and ease of use, which are all essential when working with wallcoverings,” explains Pender.

Supply55 distributes the Kala XY automatic cutter from Kala Finishing Systems, which is engineered to take a printed roll and cut the material along the X and Y axis to produce perfectly finished wallcovering panels ready for installation. Depending on the application, the wallcovering is produced into a sheet or rewound to a core.

Roll devices like Colex Finishing, Inc.’s Fotoba XLD 170 WP adjust cutting in real time to deliver accurate finishing in both the slitting and crosscutting. According to Keith Verkem, senior product manager/national sales manager, Colex, this allows the automatic XY cutter to always deliver a 90 degree corner/perfect rectangle.

“Current XY trimmers/cutter platforms have a lot of versatility in the market. Some have more automated features for continuous roll processing workflows,” notes DiVarco.

On the opposite side of the equation, he advocates that wallcovering jobs at higher volumes benefit from utilizing flatbed cutters. “Modern flatbed cutting platforms typically have modules or roll holding devices for roll processing workflows. These XYZ cutters switch back and forth between contour cutting and square cut panels. The CCD registration cameras allow for precision on jobs without bleed, which are beneficial for wallcovering projects that do not have overlap,” continues DiVarco.

Camera systems enable flatbed cutting systems like Elitron’s to easily cut all sizes and types of wallcoverings. “The print on the panels are digitally recognized and the relative cutting files loaded automatically for immediate cutting,” explains Caroline Anne Bell, marketing coordinator, Elitron.

While flatbed cutters can also be used for cutting wallcoverings, Pender says they “are not nearly as efficient as an XY cutter and come at a much higher price point. The most effective and accurate way to finish wallcoverings would be with an automated XY cutter. Many shops utilize both technologies. Higher value jobs requiring contour cutting or routing of rigid materials are sent to the flatbed cutter while square or rectangular image formats like wallcoverings are processed on an XY cutter.”

“For certain materials—paper, vinyl—roll cutters can be a bit faster. Top-quality flatbed cutters tend to be far superior in terms of versatility, accuracy, and automated workflow options. Achieving the required level of accuracy for these demanding applications involves not only a perfectly accurate drive system and material advancing, but also highly precise setup and registration features generally available only on sophisticated flatbed systems,” advocates Drury.

Flatbed cutters are well suited for contour cutting wall decals, says Stevens. One reason is versatility. Especially in terms of flatbed laser cutting systems, these devices can process paper, film, and fabric. However, he cautions, lasers are not recommended for processing any vinyl materials that contain PVC or chloride—so it’s important to know the composition of your material before you invest in a cutting system.

Get Specific (Tools)

Knives, blades, lasers—is one more ideal over the other for finishing wallcoverings?

With affordability in mind, DiVarco notes that XY cutters with crush or shear cut type blades offer features like horizontal and vertical slitting while also compensating for skew. “Wallpaper panel configurations on these platforms offer extra rollers for proper feedings and tension control.”

Flatbed cutters or XYZ cutting platforms generally offer a variety of tooling and this provides more choice to the print provider in terms of material and using the machine to cut panels or contour shapes. “Flatbed cutters offer a variety of tooling to process almost any job, but at significantly higher costs. Contour cutting is primarily a benefit of flatbed cutters,” says DiVarco.

“It depends on the application and the type of substrate being used. Here, too, flatbed cutters generally offer more choices in terms of modules, tools, blades, and bits, which can be tailored to the specific needs of the manufacturer,” says Drury. The modularity and versatility Zünd offers also allows for expanding wall décor offerings to include aluminum/ACM and acrylics with the appropriate routing tools.

Another example, Bell explains that Elitron’s knife cutting systems are multi-functional and each cutting head comes with up to five tools. The cutting heads are configured to suit individual production requirements and training is tailor made for each customer.

With laser cutters, there is the advantage of a non-contact process. “The material remains in place during the cutting process through downdraft suction, carefully securing the material without warping or stretching,” says Stevens. “An optional vacuum table can keep materials from shifting during processing using a light suction, ensuring correct focusing over the entire surface.”

Other benefits of laser cutting, according to Stevens, include “cutting materials are completed efficiently and at an accelerated pace compared to traditional knife or blade processing. Additionally, the laser seals the edges of materials as they are cut so you won’t have to worry about fraying when laser cutting textiles or other materials that may require any additional post-processing steps.”

The Best Unit

A print provider needs to determine the best finishing solution for the job at hand.

The material being printed to and then cut is a consideration in addition to a number of other factors. “Print providers should look at technology versatility, the efficiency of production, and especially the materials they plan to process when determining the best finishing unit for their business,” recommends Stevens.

Plan for now, but also keep future needs in mind. “Even though the investment in a modular, higher end system that is both versatile and adaptable may be a bit more significant at the outset, it will pay off handsomely in terms of accuracy, efficiency, and longevity. The ability to add tooling, material handling, and workflow automation when the need arises is priceless when compared to having to start all over from the ground up with a new and different machine,” suggests Drury.

Finishing Wallcoverings

It might not be the most intricate process but finishing wallcoverings still involves some thought. Whether wallpaper panels or contour cut wall graphics, either benefit from XY cutters and/or flatbed solutions.

Jun2023, Digital Output