By Cassandra Balentine

Productivity is essential to a successful sign shop. While much attention is paid to how many feet per minute a wide format printer can produce, finishing is a crucial part of the puzzle. Luckily, manufacturers of router/cutters as well as laser machines focus on speed and precision to eliminate finishing bottlenecks on a production floor.

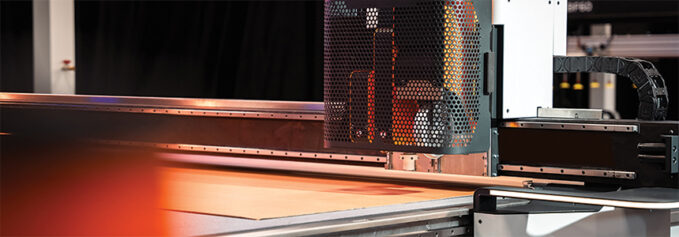

Above: The Kongsberg Ultimate offers an innovative drive technology, an acceleration rate of up to 2.74G, and a cutting speed of 168 mpm.

Optimal Options

Countless manufacturers offer cutting solutions for wide format print service providers (PSPs) handling a variety of materials, from corrugate to plastics, fabrics, and everything in between.

Colex Finishing, Inc.’s Sharpcut SXC1732 is its flagship cutter. According to Keith Verkem, national sales manager/product manager, Colex, this unit offers a conveyor system for automated loading and off loading of roll and rigid media. “There are optional products such as board loaders and take-up roll systems to further automate. With a single-piece steel welded frame we offer high-quality routing/CNC as well as fast knife cutting.”

Graphco’s SD Italy high-performance hybrid CNC routing and cutting solutions meet the needs of the signage market, among many other segments, says Chris Manley, president, Graphco. The Augusta F150R PRO boasts operating speeds of five feet per second with over 1.2 g-force (G) acceleration from cut position to cut position. It also offers electro spindle drives sized up to 13 kilowatt (kW).

The Kongsberg Ultimate is a new digital cutting platform from Kongsberg Precision Cutting Systems (PCS), which targets corrugated production with high levels of productivity, precision, and safety. “It features a new, innovative drive technology, an acceleration rate of up to 2.74G, and a cutting speed of 168 meters per minute (mpm),” shares Stuart Fox, president/CEO, Kongsberg PCS.

Mimaki USA, Inc. recently introduced the CFX Series of flatbed cutting plotters, which Josh Hope, senior manager, segment marketing, Mimaki USA, says offer speed, precision cutting, and flexibility to address applications in sign and graphics such as decals, labels, point of purchase displays, signs, and fixtures. “They can also be used in packaging for folding cartons and cardboard processing; and in industrial cutting applications.”

The Zünd Q-Line with BHS180 is the company’s latest flagship digital cutting system. It targets the corrugated display market in the graphics/packaging industry. It features a stable, mineral-cast substructure with a new linear drive system, lightweight but strong carbon fiber reinforced beams, along with an UNDERCAM and robotic board handling system, plus fully automated tool management.

Laser cutters are another option. The OptiFlex is Kern Laser Systems’ flagship large format model. It is available in a range of table sizes and laser wattages. “The flexibility of laser cutting and engraving metals and non-metals is a significant advantage. From stainless steel and aluminum to wood, plastics, and foam, the OptiFlex has you covered,” comments Nicole White, content strategist, Kern Laser Systems.

Distributed by Matik, Inc., the latest addition to SEI Laser’s X-Series of plotters delivers some of the fastest, most accurate laser cutting plotters available for textile, corrugated, and signage applications, according to Steven Leibin, president, Matik. “The X-Series speed is revolutionary—up to five times faster than competitive machines.”

Best of Both Worlds

In addition to speed, precision is equally as important to PSPs. Therefore it is essential that advancements to productivity do not come at a cost to accuracy and vice versa.

Beatrice Drury, communications manager, Zund America, Inc., feels that it is possible to achieve both high speeds and precision using the latest cutting technologies. However, it requires both technological advances in the drive system and in controlling the movement of the beam(s) and cutting head(s)/modules as well as a supremely stable base to counteract the forces inherently involved in generating these previously unattainable levels of speed.

“The build quality of industrial cutting systems delivers products that are fast and precise,” agrees Hope.

With a ridged and engaged drive system and a single-piece steel welded frame, Verkem says Colex offers both speed and precision.

The stable positioning and control of the substrate being processed is another critical aspect for successful cutting. For this, the Graphco SD Italy machines use Becker air pumps and intelligent zone control technology—up to 48 zones—to hold even porous materials in place for precise and high-speed production. “Our main focus is on helping customers create the most efficient workflow,” shares Manley.

With its meticulously designed custom carbon fiber beam, Fox says the Kongsberg Ultimate ensures unparalleled stiffness and consistently applies a 50kg downforce. “The tool head camera further elevates its precision, making every cut meet the highest accuracy standards.”

It is critical that equipment is manufactured with accuracy in mind, believes Hope. The Mimaki CFX cutting plotters employ a ball screw on the Z-axis that allows for not only high pressure, but also highly accurate cuts with less breakage over multiple cuts. In addition, the CFX Series has a backside cutting mode—patent pending, which is available when combined with an optional camera unit. The system uses the camera unit to recognize registration marks printed on the surface and material edges.

The Zünd Q-Line offers a specified speed of 2.8 meters per second. “Beyond machine speed, however—the trees, if you will—there is always the forest to consider, i.e. the digital workflow as a whole that is responsible for converting printed substrates into finished/cut pieces and products. A lot of Zünd’s recent developments are devoted to workflow automation because if there isn’t an efficient and reliable overall production workflow in place, any gains in raw cutting speed are effectively annihilated,” explains Drury.

There are also achievements on the laser side of wide format cutting. “Achieving high speed and precision in today’s large format laser cutting systems is indeed a reality, thanks to significant technological advancements in laser sources,” comments White.

These include high-performance servo motors and drivers with a belt driven X-axis, which give Kern Laser Systems’ machines the capability to reach speeds up to 150 inches per second (ips) for engraving and cutting speeds of up to 20 ips.

“When processing materials at high speed it is important to choose a powerful laser that will not limit the speed you are able to cut or engrave at. Another important characteristic of the laser is size and weight. The laser should be compact and lightweight in design so it can be installed on a large format machine without negatively impacting the performance of the system,” recommends White.

SEI Laser’s X-Series of laser plotters deliver speeds of up to 300 mpm, which Leibin attests is double the fastest speeds of competitors’ newest machines. “The SEI Laser X-Series features brand-new cartesian movement of the laser head obtained by two carbon fiber axes, driven by four high-performance linear motors to deliver lightning fast speeds and high accuracy cutting performance.”

Considerations for Cutting

When investing in a cutter, there are many considerations, from investment cost to productivity, accuracy, safety, uptime, and footprint. When narrowing it down based on speed and precision, finishing vendors have worked hard to ensure that one is not sacrificed for the other with strategic advancements in everything from workflow to media handling.

Jun2024, Digital Output